Zhengzhou Bai-ott New Material Co., Ltd was registered in 2008 as a specific export company in conveyor belt maintenance products system manufacturer. After more than 10 years development, till now we have four departments commit to product quality and service supervision from raw materials till after-sale service, which are R&D laboratory center comply with Chinese national standard, Product branch, Business branch and Engineering branch.

Our one stop conveyor line maintenance products also developed to three complete systems can meet 80% of your requirements and product demand. The first is conveyor belt support system including pulley lagging, conveyor belt cleaner, rubber skirting, impact bed, impact ceramic lining, conveyor rollers and so on, which can help improve conveyor line productivity and also help to supply a nice working environment. The second is conveyor belt repair and splicing system including vulcanizing materials, uncured rubber materials, repair epoxy and so on, which can always keep conveyor belt in a good state to prevent influence productivity. The third is conveyor belt splicing kits system including vulcanizing press, belt fastener, mechanical joint, special tools for hot vulcanization together supply great help for conveyor maintenance work. All products in this four systems concreted together and developing more and more complete so that can bring our cooperator a very good feeling of one stop project purchase experience.

Based on the most complete products line we get many support from the global cooperators in mining machine maintenance field and has successively established agents in many developed and developing countries till now, such as Japan, Canada, Australia, Greece, Peru, Indonesia .... to help some smaller distributors quicker get goods and service require in the whole world. We also supply timely technical training for different country’s agents to keep them also always obtain State-of-the-art maintenance technology so that they can soon provide the best maintenance solutions for various mining environment and conveyor belt problems, all of these training based on our Chinese mother branch’s so much construction and production experience in more than 10 years of development.

In general our products and service mainly for all field which doing materials transportation projects and who have any heavy duty adhesive products requirements. If detailed different them will be mainly these field.

Mining application cover more than 50%, such as coal mining and washing, oil and natural gas mining, ferrous metal mining and dressing, non-ferrous metal mining and dressing, non-metallic mining and dressing, other mining industries. There industries always have very long conveyor belt to transport any materials for long distance. So the complicated environment usually damage conveyor belt will need time in time maintenance.

Harbour, power plant and cement such as industries application can cover more than 40%. Conveyor line of these industries working usually 24 hours for 7 days year by year to produce enough energy and gives for the next lines, so conveyor belt repair system and support system is a necessary part to bring assistant sometimes.

The rest part is some small conveyors be like food factory, express, logistics, airport, grain factory... The most quickly maintenance products and construction skills can give enough support for above industries and also small conveyors and belts replaceable also very necessary when urgent because time is profit for these small industries.

What’s more, for tire repair and truck maintenance store which need wear abrasive rubber products, we are also a very good choice.

We will continuously complete our products and service lines so that can provide more and more products to our end users, skills and technology to our agents, safe and healthy product formula to this field, timely support to our partners.

Patent

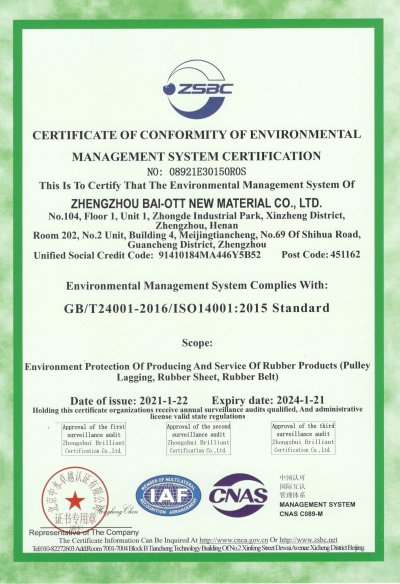

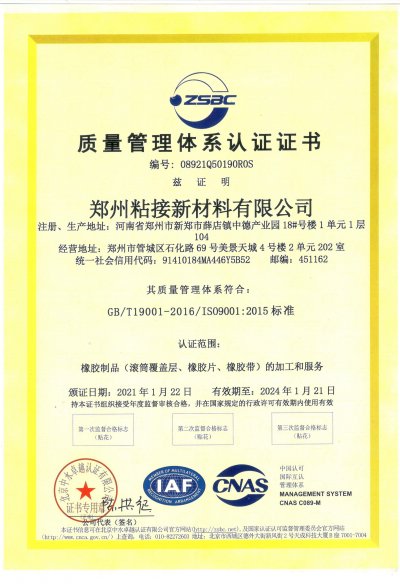

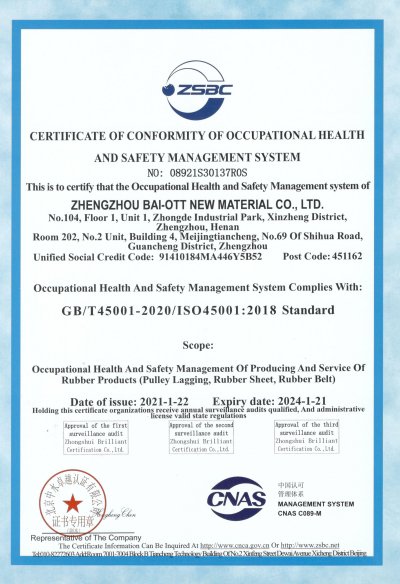

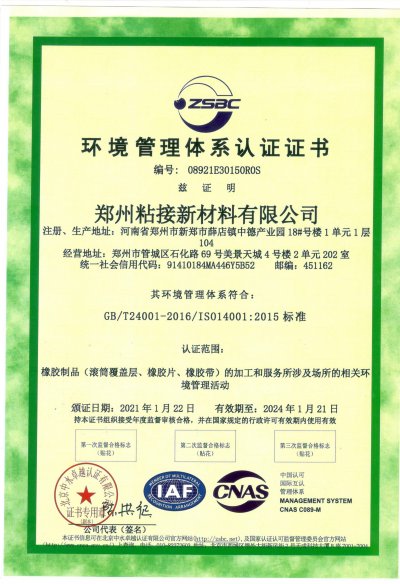

Certification

Laboratory

Manufacture

Exhibition