What is conveyor impact bars?

The high-elasticity special rubber layer fully and effectively absorbs the impact force when the material falls, which greatly reduces the impact on the conveyor belt when the material falls, and truly improves the stress condition of the blanking point. And the special UHMW high molecular polyethylene surface is used to minimize the friction coefficient between the conveyor belt and the impact bars, and has good wear resistance. The use of the impact bar ensures the contact between the conveyor belt and the surface, and the force is uniform, which effectively prevents the longitudinal tear of the belt caused by the breakage and falling off of the idler, and greatly reduces the longitudinal direction of the belt after being penetrated by sharp objects or sharp materials. probability of tearing.

What is the advantages of conveyor impact bars?

1. The surface contact of the impact bars prevents the damage to the conveyor belt effectively.

2. The conveyor belt is evenly stressed at the blanking port, which greatly reduces the daily repair and maintenance costs.

3. Effectively eliminate material splashing and leakage caused by non-uniform force on the conveyor belt.

4. The smooth surface of the ultra-high density polyethylene minimizes the friction when the conveyor belt is running.

5. The arc design on the surface of the polyethylene layer ensures the smooth running of the conveyor belt.

6. The ultra-high elastic special rubber layer can absorb the impact force of the material to the maximum extent.

7. The parts of the impact bars are connected by hot vulcanization process, which is compact and firm.

What is the composition principle of the impact bars?

Surface structure : The material adopts ultra-high polyester resin board and polyurethane material. It mainly adopts ultra-high rubber grinding particle size with good adhesion and low technical requirements, and has excellent lubricating performance. It is very suitable for operation with excellent performance from the conveyor belt.

Features of polyethylene board

1. Higher wear resistance, its wear resistance is 4 times higher than nylon-66, 9 times higher than HDPE and HPVC, and 9 times higher than stainless steel compared with metal, wear resistance in erosion environment The rate is about 20 times that of A3 steel;

2. High impact resistance, the impact strength is 2 times that of PC and 5 times that of ABS.

3. High self-lubrication, low friction coefficient, about 0.05-0.11, comparable to PTFE, and better than steel and copper with lubricating oil. Under water lubrication conditions, UHMW- The kinetic friction coefficient of PE is half lower than that of PA-66 and POM;

4. Excellent non-water absorption, the water absorption of UHMW-PE is low, 0.01% is only 0.1% of PA-6;

5. Excellent non-stickiness, it shows that the adsorption force is very weak, and its anti-sticking ability is second only to PTEF with the best stickiness in plastics.

6. Excellent chemical corrosion resistance, can resist various corrosive media (acid, alkali, salt) and organic media within a certain temperature and concentration range;

Rubber Elastomer

When the impact bar is impacted, it mainly uses the elastic material to play a good buffering role through its own physical elasticity. Therefore, the rubber elasticity must meet certain conditions. Internationally, the rubber elasticity of the buffer strip is about 55 degrees of Shore hardness. (If the rubber is used underground, it must be treated flame retardant rubber), and has a certain tear resistance, tensile strength, and elongation at break.

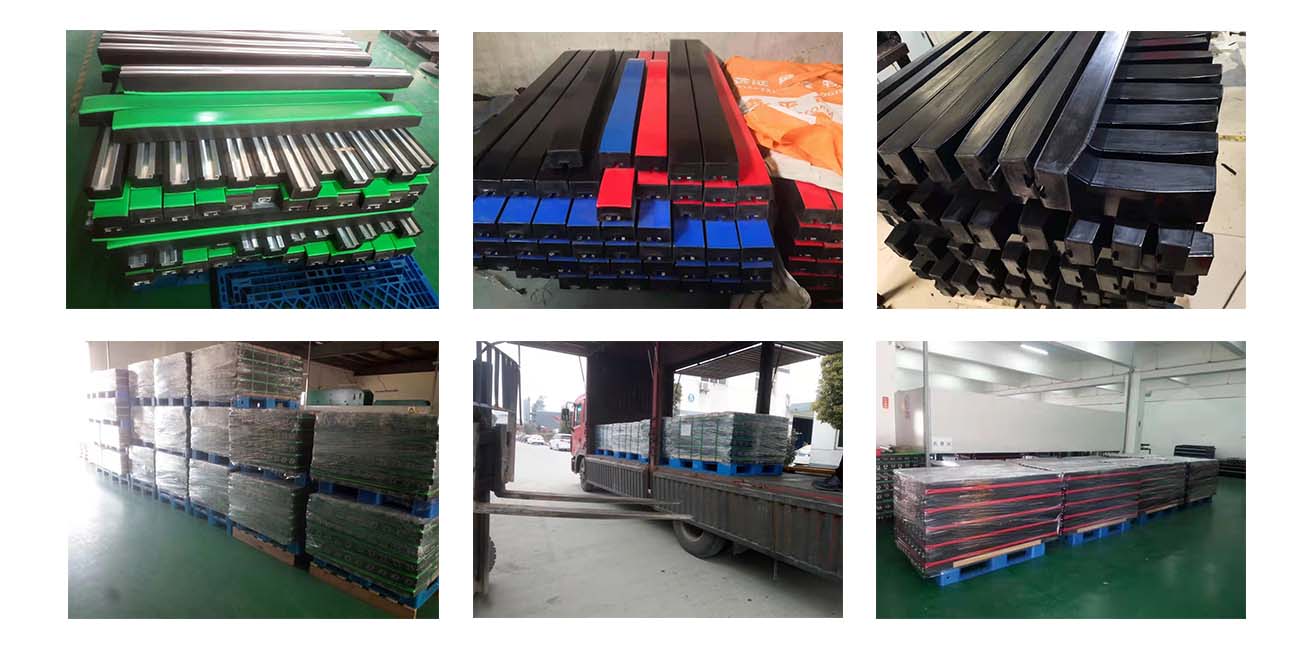

What is the impact bar's classification?

1. Impact bars are generally classified according to the usage environment, and are mainly divided into two types: high-elasticity impact bars and flame-retardant impact bars.The specifications are mainly determined by the specific use of the customer, and the international more commonly used length are 1220mm and 1500mm,width is 100mm and the thickness is 50mm, 75mm or 100mm.

2. There are two types of belt conveyor impact bars,one is underground flame retardant, and the other is ground. The underground one is black (only black), the ground is red or other colors, and the flame retardant level is V0. The electrostatic level is 3*10*8, but both molecules are above 5 million.

How to install it?(accordint to operating Environment)

1. Bolt fixing,: welding fixing holes at the bottom of the buffer bed, and fixing it directly on the belt conveyor frame by bolts;

2. The belt frame is narrow, which is inconvenient to fix with bolts. It can be fixed by bayonet with U-row bolts;

3. The distance between the upper and lower belts in the tubular conveyor is small, and the belt conveyor frame is narrow, and the impact bed bracket is directly welded to the belt frame;