Head Drive Drum Ceramic Pulley Lagging

Brand: BAI-OTT or OEM

Thickness: 12mm,15mm,20mm or Custom

Feature: Wear-Resistant

Installation: Head Drum and Tail Drum

CN Bonding: Available

Material: Ceramic+Rubber

Sample: Provide

Product Inspection:Available

MOQ: 1 Square Meter

Lead time:Ready to ship in stock

View more Pulley Lagging Sheet from BAI-OTT

Description

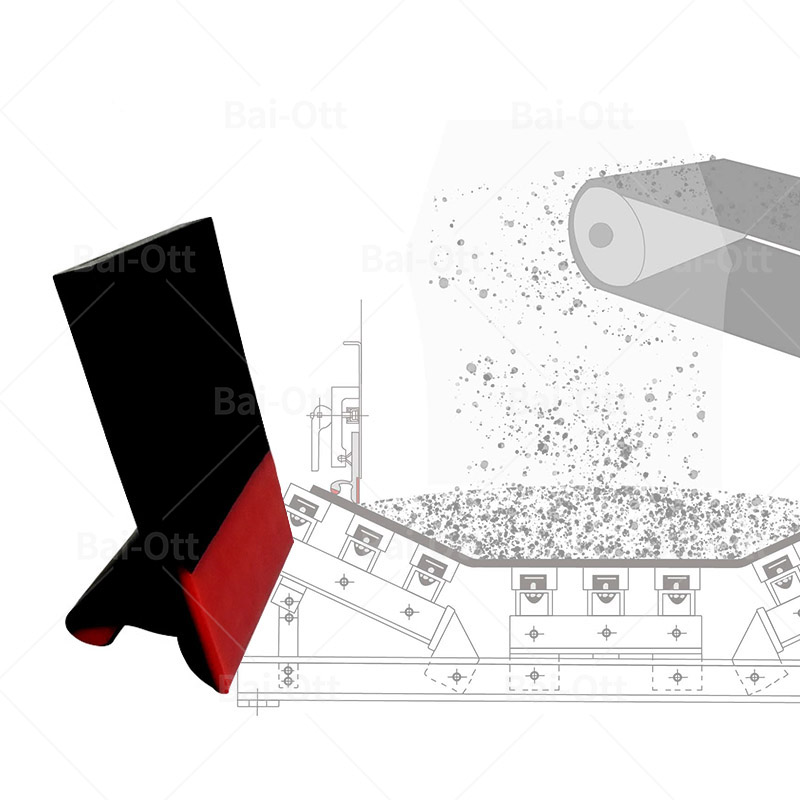

High Friction Ceramic Pulley Slide Lagging For Conveyor Belt Drum

Ceramic pulley lagging is used for drum lagging in wet and muddy conditions, which has the characteristics of high friction, anti-slip, high wear-resistant, heat resistant. And can provide distinguished grasping force between driving roller and conveyor belt, accommodate to all kinds of muddy, humid, and sticky working environment, also work well to solve severe wear and slipping problems of the drive wheel, tailwheel, tension pulley, and roller, ensuring the conveyor belt running well. And especially suitable for the muddy and damp difficult conveyor working environment because the ceramic is strong enough to protect the tiles and conveyor pulley.

Our pulley lagging sheet for conveyor belt drum includes: Head drum hot vulcanized ceramic pulley, Tail drum anti slip ceramic pulley,Head drum grooved diamond pulley,Hemp impression Plain pulley, Bolt on heat resistant ceramic pulleyNand high friction weld on rubber pulley.

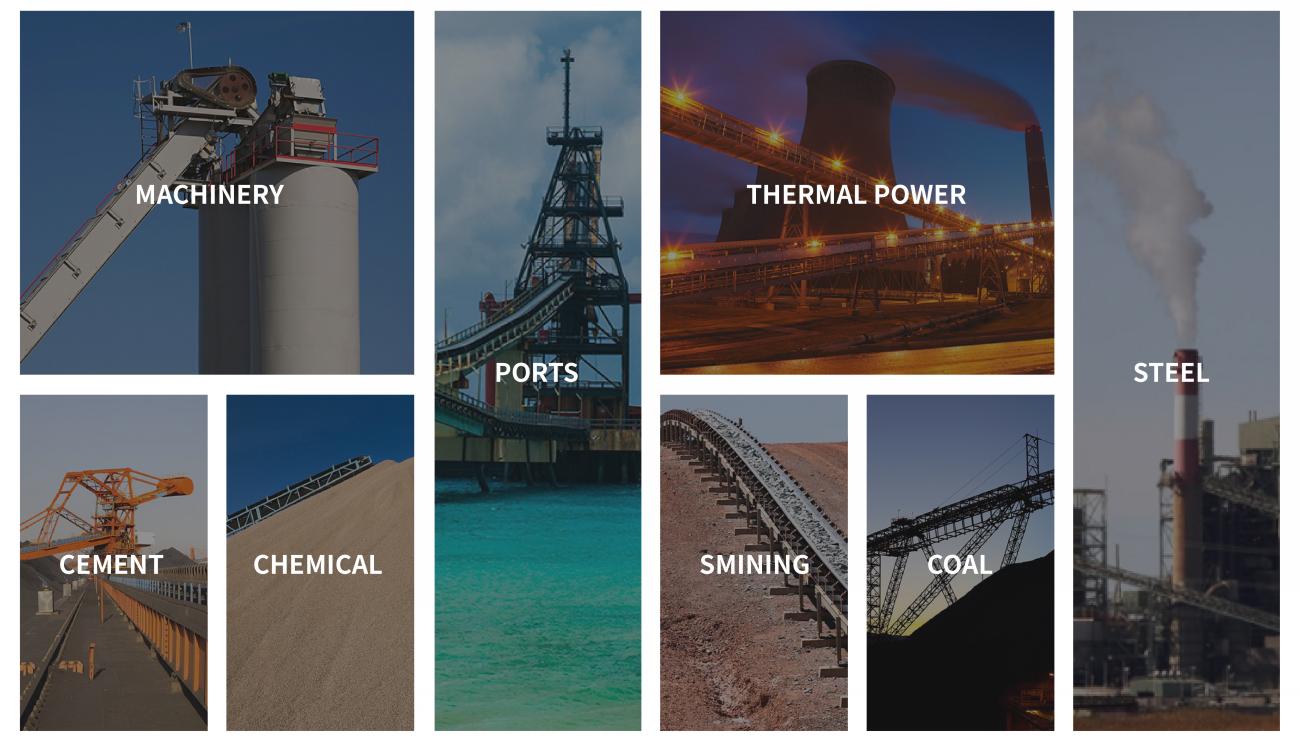

Coal washing plant, Cement plant, Metal factory, Metallurgical plant, Crusher like ceramic pulley lagging because their conveyor tile location in the damp places, the ceramic outstanding in high wear-resistant can better belt the conveyor running.

| Order No. | Product Name | Dimension(mm) |

| 3531250 | Ceramic Pulley Lagging Sheet | 12*500*10000 |

| 3531550 | Ceramic Pulley Lagging Sheet | 15*500*10000 |

| 3532050 | Ceramic Pulley Lagging Sheet | 20*500*10000 |

Further dimensions on demand

Advantage

Ceramic blocks containing 95% aluminum oxide embedded into rubber sheet.

Single or double,plane or convexity ceramic can be chosen.

Hardness same as conveyor belt so better friction and protection to the belt.

Abundantly elastic basement rubber can protect conveyor belt well.

Ceramic coverage about 38%.

OEM for logo, ceramic block type and is available.

Usually produced as long as drum size by piece from 1250-4000mm.

CN bonding layer on back of the lagging so can directly brush glue without grind step.

High productivity and have stock so lead time always within 3 days.

Specifications

| Type | Thickness/mm | Width/mm | Ceramic coverage rate | CN Bonding layer | Drawing |

| Super wear abrasive | 12/15/20 | ≤500 | 38% | Yes or no | Have |

| Economic | 12/15/20 | ≤500 | 20% | Yes or no | Have |

| No ceramic | 12/15/20 | ≤500 | 0 | Yes or no | Have |

| Ceramic Block Data | Rubber Part Data | ||

Aluminum Oxide(min)Al2O3 | 92% | Polymer | NR/SBR |

Specific Gravit | >3.7g/cm3 | Specific Gravity | 1.13±0.03 |

Hardness(Moh ,s) | >9t | Shore Hardness°A | 60±5 |

Tensile Strength(Mpa) | ≥320Mpa | Elongation at break%Min | 450% |

Comp.Strength(Mpa) | ≥2000 Mpa | Tensile Strength | 17.5N/mm2 |

Flexural Modulus(Mpa) | 32.0 | Abrasion Loss | 150mm2 at 10N |

Water Absorption | 0% | ||

![[pics:title]](/static/upload/image/20211223/1640251453255291.jpg)