How to choose the conveyor buffer bed

The buffer bed of belt conveyor is the key equipment commonly used in the conveying system. It is used under the guide chute of the belt conveyor and under the belt at the blanking point to cushion the impact of falling materials on the conveyor belt. The traditional buffer idler has poor buffer capacity, can not well absorb the strong impact of material falling, and is easy to break the support idler; In addition, the supporting idler is in linear contact with the conveyor belt, and the two rollers are suspended, which is easy to be penetrated by materials or other sharp hard objects, resulting in longitudinal tearing of the belt between the idler and the blanking port; The surface of the supporting roller is inelastic, and the surface is easy to adhere to materials and wear the belt after the long-term operation, which will lead to belt deviation in serious cases; The belt between the two rollers is easy to sag, making the belt in the section of the blanking port wavy, making the sealing of the blanking port poor, resulting in material scattering and environmental pollution. The buffer bed can not avoid the problem of replacing the buffer idler. At the same time, it can improve the production capacity and reduce maintenance costs. The ingenious design of the buffer bed changes the disadvantages of the traditional design, makes the buffer strip in the blanking area contact with the conveyor belt face-to-face evenly, and provides support for it, effectively preventing the uneven stress of the conveyor belt during material transportation, and greatly reduces the maintenance and repair caused by the impact damage of the conveyor belt. The use of the buffer bed is to effectively prevent damage to the conveyor belt, prevent material splashing, reduce the cost of daily repair and maintenance, and ensure the smooth operation of the conveyor belt.

Selection of buffer bed:

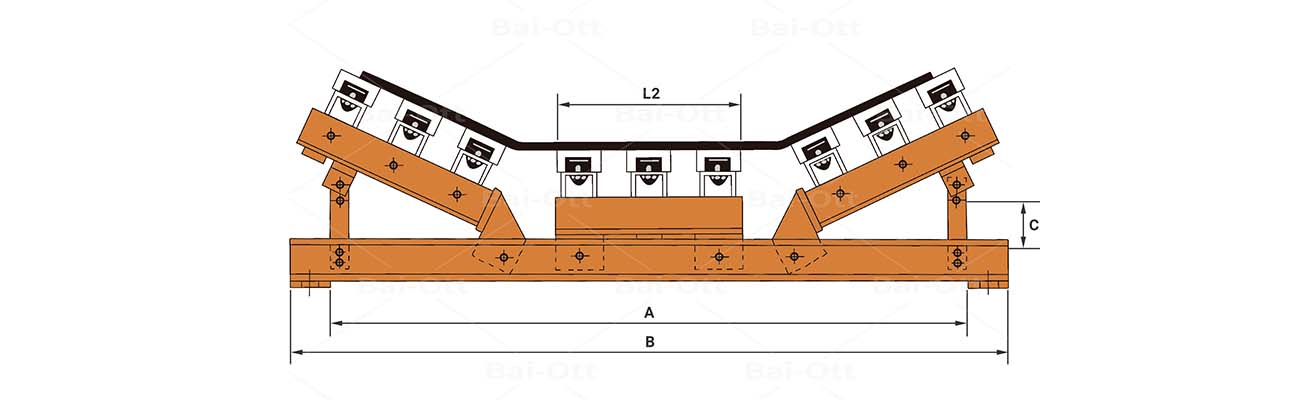

According to the installation and use requirements, it is divided into parallel buffer bed, hanging buffer bed, sinking buffer bed, and large angle buffer bed. According to the industrial and mining conditions, it is divided into wear-resistant buffer beds and flame-retardant buffer beds, composite heavy-duty buffer beds, adjustable buffer beds, super heavy-duty buffer beds, etc. Reasonable selection is particularly important. The buffer bed is designed and customized one-to-one according to different working conditions- Generally, the selection is based on the conditions of bandwidth, buffer strip length, whether there are flame retardant requirements, conveying medium, blanking height, management speed, medium particle diameter, transportation volume and so on.

Quality of impact bed:

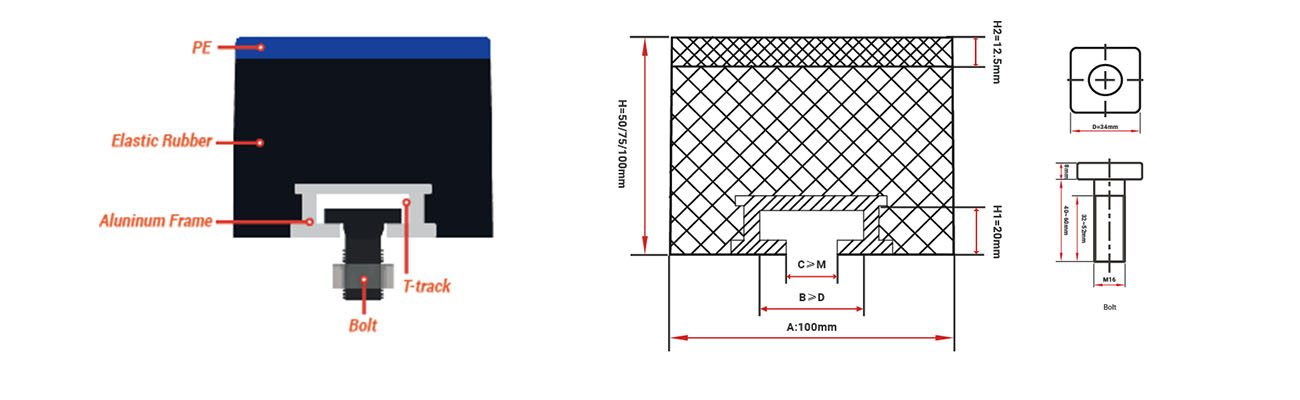

The impact bed is generally composed of three parts: buffer strip, bottom support of buffer strip, and base support, some special buffer beds also have buffer blocks, idlers, etc., but all changes are inseparable. Let's analyze the quality problems of these three parts:

1. The quality of the buffer strip is poor, the friction of the wear-resistant layer is too large, and the rubber elasticity is poor, which leads to the wear of the belt, and even the problems of glue opening and smashing.

2. The bottom support of the buffer bed has different choices under different working conditions, and the details such as the design of both ends are also very important. Insufficient support will cause problems such as the destruction of the buffer strip.

3. If the bearing capacity of the base of the buffer bed is not reached, it will directly affect the service life of the buffer bed, as well as details such as welding and plastic spraying.

Installation issues:

There is a certain gap between the buffer bed and the belt under normal no-load conditions. In the early stage, the engineer will design according to the on-site working conditions. In addition, the installation position of the buffer bed and other factors will also affect the use effect.

Zhengzhou Bai-ott New Material Co., Ltd was registered in 2008 as a specific export company in conveyor belt maintenance products system manufacturer. After more than 10 years of development, now we have four departments committed to product quality and service supervision from raw materials to after-sale service, which are the R&D laboratory center comply with Chinese national standards, the Product branch, the Business branch, and the Engineering branch.