What is skirting on a conveyor?

1-2 sentences about conveyor skirting

There are many factors to consider when selecting the right skirting for your conveyor. The type of material you are conveying, the width of your conveyor, and the environment in which the conveyor is operated are all important factors to consider.

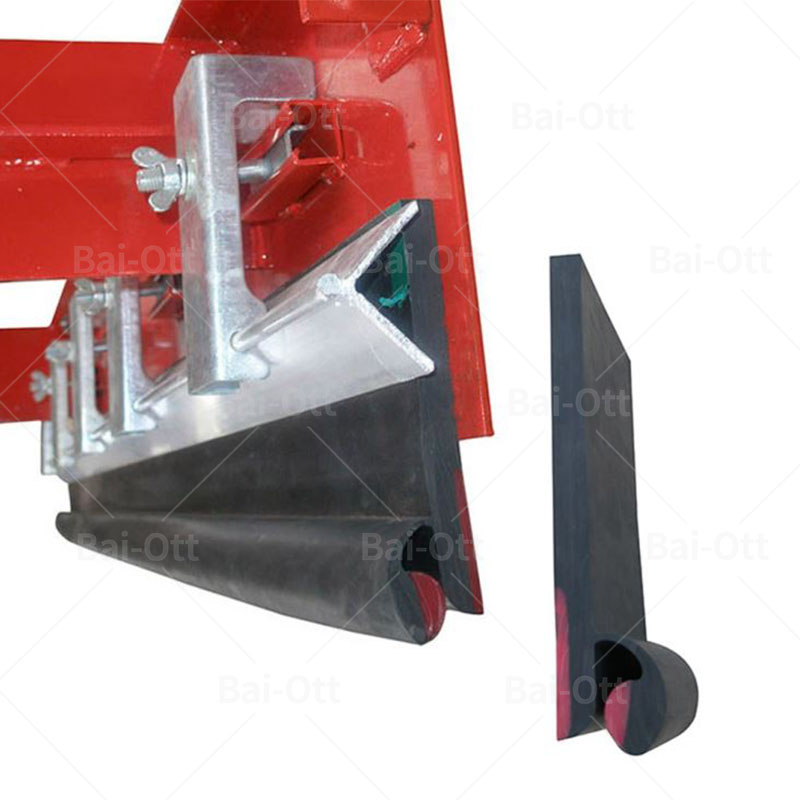

The most common type of skirting is made from rubber. Rubber skirting is flexible and can be easily replaced if it becomes damaged. Rubber skirting is also less likely to cause damage to the conveyed material.

Another type of skirting is made from plastic. Plastic skirting is more rigid than rubber and can be used in a wider variety of applications. Plastic skirting is also easier to clean than rubber skirting.

No matter what type of skirting you choose, it is important to make sure that it is properly installed and maintained.

What is skirting on a conveyor?: definition and purpose

Skirting on a conveyor is a material that is used to close the sides of the conveyor belt. It is used to keep the conveyed materials from falling off the sides of the belt and also to prevent them from being thrown out by the rotating motion of the belts. Skirting on a conveyor can be made of different materials such as PVC, polyurethane, rubber, or even metal. The most common type of skirting used on conveyors is PVC.

The purpose of skirting on a conveyor is twofold. First, it keeps conveyed materials from falling off or being thrown out by the belt’s rotation. Second, it protects the sides of the conveyor belt from wear and tear. Skirting also helps to extend the life of a conveyor belt by preventing excessive friction between the belt and conveyed materials.

How to install skirting on a conveyor: step-by-step guide

If you're in the market for a new conveyor system, one of the first decisions you'll need to make is what type of skirting to use. Here's a step-by-step guide to help you choose and install the right skirting for your needs.

1. Decide on the material. Skirting can be made from a variety of materials, including PVC, urethane, polyurethane, and rubber. Each has its own advantages and disadvantages, so it's important to choose the right one for your needs.

2. Choose the right size and shape. Skirting comes in a variety of sizes and shapes, so you'll need to measure your conveyor belt to ensure you get the right fit.

3. Install it correctly. Proper installation is a critical part of ensuring that your skirting lasts as long as possible.

The benefits of using skirting on a conveyor: list of pros

When it comes to keeping materials on a conveyor belt, there are several options available. One option is skirting. Skirting is a type of material that is placed around the edge of the conveyor belt. It is often made from rubber or PVC and helps to keep materials from falling off of the conveyor belt. Here are some of the benefits of using skirting on a conveyor:

1. Skirting can help to increase the lifespan of a conveyor belt. When materials fall off of a conveyor belt, they can cause damage to the belt. Over time, this can lead to premature wear and tear. By using skirting, you can help to prevent this type of damage from happening.

2. Skirting can also help to improve the efficiency of a conveyor system.

The drawbacks of using skirting on a conveyor: list of cons

There are several drawbacks to using skirting on a conveyor. First, it can be difficult to keep the skirting in place and properly aligned. Second, skirting can block access to the conveyor belt for maintenance and repairs. Third, skirting can create a trip hazard if not installed properly. Fourth, skirting can be damaged by debris or dropped items. Fifth, skirting can become detached from the conveyor belt and cause entrapment hazards. Sixth, skirting can interfere with proper tracking of the conveyor belt. Seventh, skirting can increase noise levels around the conveyor. Eighth, skirting can collect dust and debris, which can lead to fire hazards.

Conclusion: 1-2 sentences summarizing the article

When it comes to conveyor systems, skirting is an essential component. Skirting is used to seal the gaps between the conveyor belt and the frame, which prevents material from falling through. There are two main types of skirting: static and dynamic. Static skirting is typically made of rubber or PVC and is mounted on the conveyor frame. Dynamic skirting, on the other hand, is made of a flexible material that can move with the conveyor belt.

There are several factors to consider when choosing the right type of skirting for your conveyor system. The most important factor is the type of material you will be conveying. For example, if you are conveying fragile items, you will need a soft material like PVC to prevent damage. If you are conveying heavy items, you will need a harder material like rubber to prevent wear and tear.