High Temperature,and Heat Resistance Silicone Rubber Sheet

Brand: BAI-OTT or OEM

Wide range of hardness: 10~90 shore A;

High temperature resistance: normally work at 190°C

Low temperature resistance: normally work at -50 ~ -60°C

Colour:white,red,orange,black,blue,gray

Chemical resistance: good chemical, oil resistance

Sample: Provide

Product Inspection:Available

Lead time: Ready to ship in stock

View more Silicon Rubber Sheet from BAI-OTT

Description

Silicone Rubber Sheet is a highly active adsorbent material, which belongs to amorphous material. Silicone Rubber Sheet is mainly composed of silica, which has stable chemical properties and does not burn.To understand silicone rubber plate, we must first understand silicone rubber. Silicone rubber, thermal vulcanization (HTV), room temperature vulcanization (RTV), including room temperature vulcanization, condensation reaction and addition reaction. High temperature silicone rubber is mainly used to manufacture various silicone rubber products, while normal temperature silicone rubber is mainly used as adhesive, filling material or mold. Hot vulcanization type is the most widely used type. Heat vulcanization type can be divided into methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ), methyl vinyl phenyl silicone rubber (pvmq) (low temperature resistance, radiation resistance), and other types of silicone rubber, such as silicone rubber for eyes and fluorosilicone rubber.

Generally speaking, Silicone Rubber Sheet can be divided into silicone gel and inorganic Silicone Rubber Sheet according to its properties and ingredients. It is usually a series of inorganic materials prepared by acid and Silicone Rubber Sheet after aging. The chemical formula is Silicone Rubber Sheet, and the material is amorphous. NH2。 Insoluble in water and any solvent, non-toxic and tasteless, stable chemical properties, and does not react with strong alkali, hydrofluoric acid and other substances.

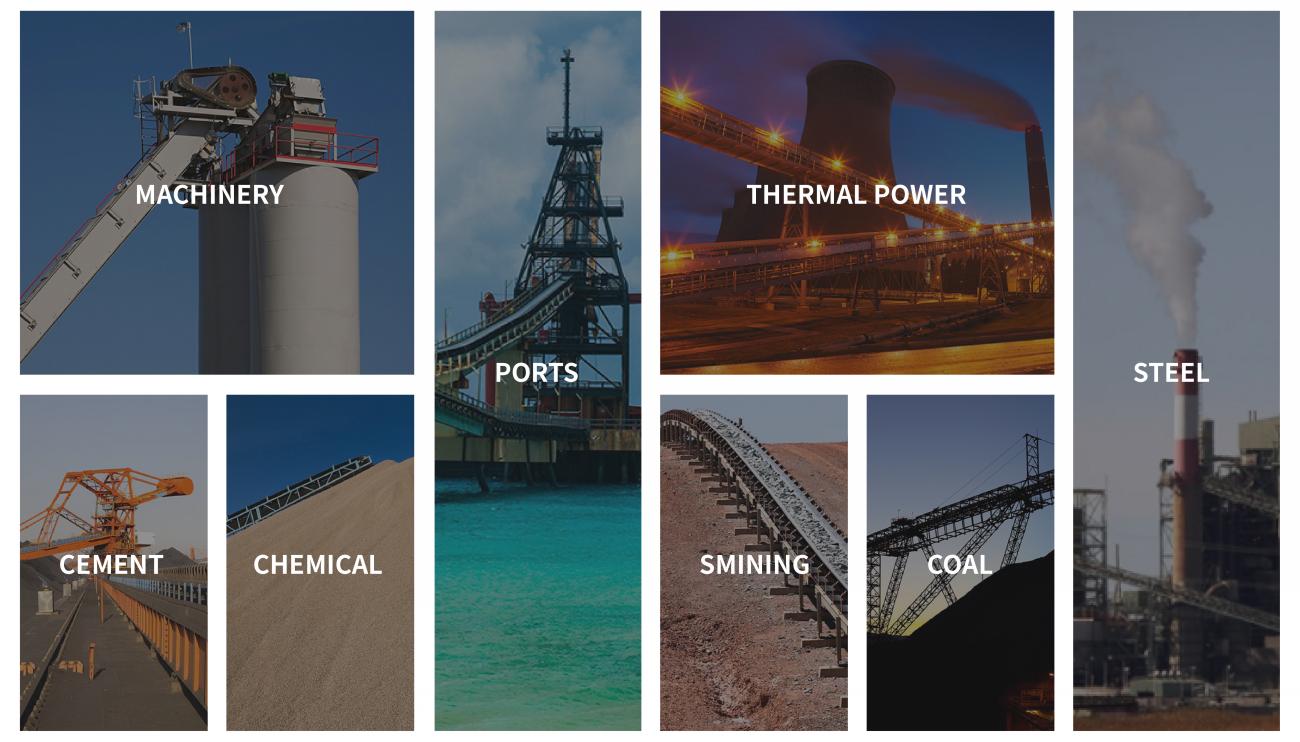

It is easy to understand the use of silicone rubber from its properties. It can be said that silicone rubber plate is widely used. It is not only used as special materials in aviation, advanced technology and military technology departments, but also used in various departments of the national economy. Its application scope has been extended to construction, electronics, textile, automobile, machinery, leather paper, chemical light industry, metal and coating, medicine and other fields. Medical treatment, etc.

Advantage

Optional thickness

Color adjustability

Simplicity of construction

Stability of quality

Good recoil

Excellent skid resistance

Specifications

Installation Construction:

1、 Open an aluminum mold, iron mold or copper mold, which can be closed up and down, like a box, and clean the mold first.

2、 Apply a layer of release agent inside the whole mold (the release agent can be Vaseline or detergent) and carry out the following operations after it is dry.

3、 Fill the aluminum plate at the bottom of the mold (it is better to punch a small hole on the uppermost aluminum plate to enhance the adhesion between silica gel and aluminum plate), place the aluminum plate, clean the aluminum plate, and apply adhesive on the aluminum plate. The filled aluminum plate can be multiple, and the one that really works is the top one. (the purpose of filling multiple aluminum plates is to adjust the thickness of the pressed silica gel plate, and put the bronzed silica gel and aluminum plate together)

Note: painting Tianna water on the top aluminum plate also helps to increase the adhesion between silica gel and aluminum plate.

4、 When cutting silica gel, the silica gel plate should be 1 cm smaller than the aluminum plate, because the silica gel will extend around in the process of pressing. Then spread the silicone board slowly from one end to the aluminum board, and then roll the wooden stick on the silicone board from one end to the other. The purpose of this is to drive the air. In this way, there will be no air and bubbles between the pressed silica gel and the aluminum plate, and the bonding effect will be better.

| Items | Silicone rubber roller and rubber sheet |

| Type | Roller: With metal core and without metal core Sheet: Pure silicone rubber, with fabric, with glass cloth, with steel wire |

| Density | 1.3 |

| Breaking Tenacity | 6 Mpa |

| Enlongation | 300% |

| Temperature | 200-320℃ |

| Hardness | 30-90 shore A |

| Thickness | 0.1mm-100mm |

| Size | Custom as your need |

| Color | Any color on Pantone card |

RIT-A 1st Generation HX1100 | RIT-B 2nd Generation HX2100 | RIT-C 3rd Generation HX1100 | RIT-D 4th Generation HX1100 | |

| Hardness, Shore a | 70 ± 2 | 72 ± 2 | 65 ± 3 | 75 ~ 78 Working surface 60 ~ 65 Buffer surface |

| Tensile strength, Mpa | 11.5 | 14.2 | 16.8 | 10.8 |

| Tearing strength N/mm | 45 | 47 | 39 | 48 |

| Temperature resistant C | 220 | 240 | 180 | 250 |

| EVA resistant (Comparison) | Weak | Medium | Strong | Strong |

| Normal service life (times) | > 2000 | > 3000 | > 4000 | > 5000 |

| Appearance and color | Transparent One side smooth+one side rough Double side smooth | Red/gray One side smooth+one side rough Double side smooth | Black; One side smooth+one side rough Double side smooth | Black / gray One side smooth+one side rough ; |

Model | Tensile strength Mpa | Tear Strength N/mm | Hardness Shore A | Elongation % | Color | Appearance |

RIT3111 | 6.5 | 26 | 55 ± 5 | 450 | Transparent | Double Smooth |

RIT311 | 6.5 | 26 | 55 ± 5 | 450 | Transparent | One smooth+one fabric |

RIT312 | 6.5 | 26 | 55 ± 5 | 450 | Rust red | Double Smooth |

RIT3122 | 6.5 | 26 | 55 ± 5 | 450 | Rust red | One smooth+one fabric |

RIT3211 | 8.0 | 32 | 55 ± 5 | 650 | Transparent | Double Smooth |

RIT3212 | 8.0 | 32 | 55 ± 5 | 650 | Transparent | One smooth+one fabric |

RIT3221 | 8.0 | 32 | 55 ± 5 | 650 | Rust red | Double Smooth |

RIT3222 | 8.0 | 32 | 55 ± 5 | 650 | Rust red | One smooth+one fabric |

Note:Thickness:2~10mm;Max.Width:4000mm

Model | Tensile strength Mpa | Tear Strength N/mm | Hardness Shore A | Elongation% | Color | Appearance |

HX211 | 6.5 | 26 | 60~75 | 450 | White transparent | Double side smooth |

HX2211 | 9.0 | 32 | 50~70 | 650 | Gray transparent | Double side smoot |

Model | Tear Resistant N/mm | Adhesive force N/mm | Hardness,Shore A | Elongation. % | Color |

HX2321 | 80 | 2.5 | 55+5 | 350 | Rust Red |