Color Coated Sheets Conveyor Hood Covers

Brand: BAI-OTT or OEM

Feature: Abrasion and impact resistance

Size: Available

Material: Q235+Stainless steel

Sample: Provide

MOQ: 100 Meters

Sample: Provide

Product Inspection:Available

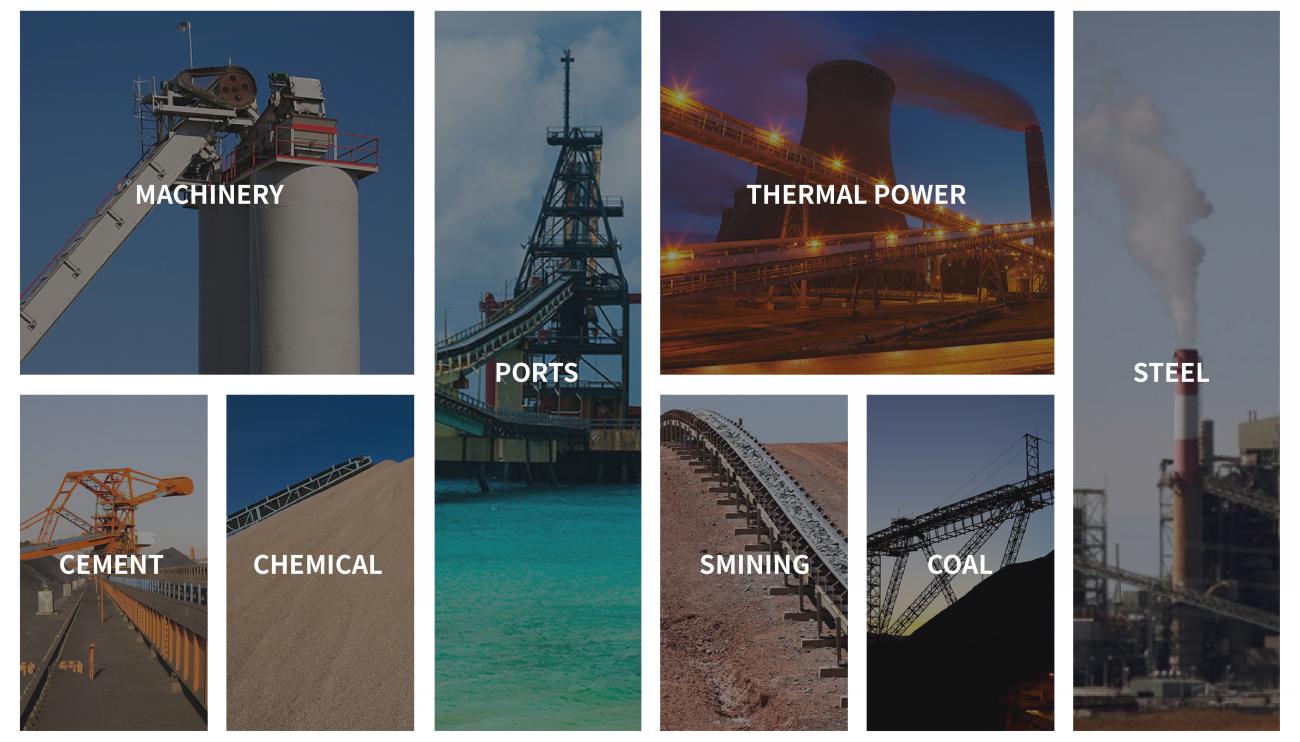

Application: Coal mines, Cement plants, Steel plants, Power plants and other factories

Lead time:Ready to ship in stock

View more Conveyor Hood Covers from BAI-OTT

Description

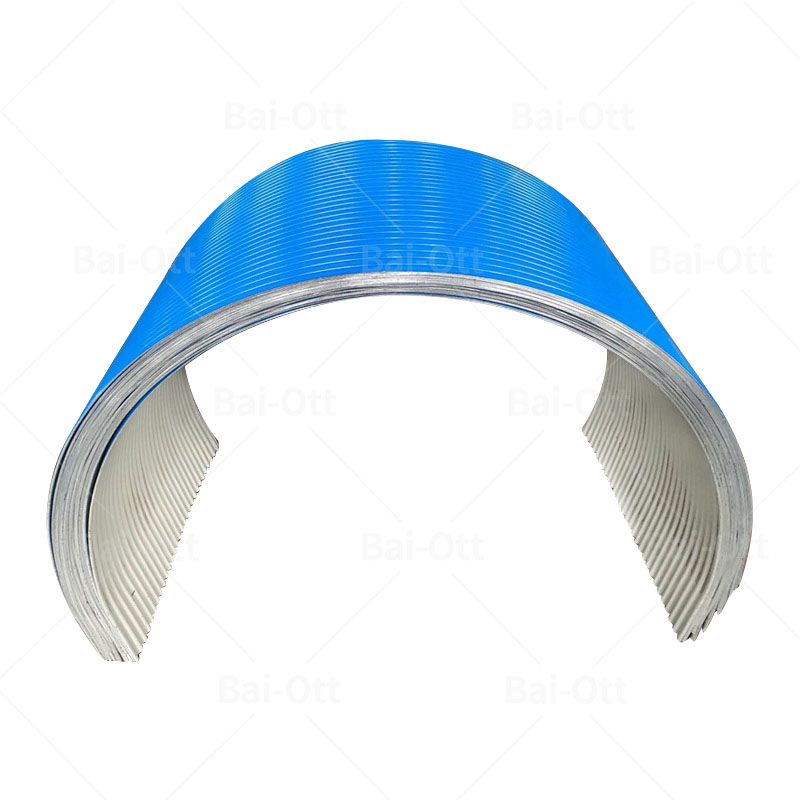

BAI-OTT Color Coated Sheets Conveyor Hood Coveris made of color steel plate. The color steel plate coating is made of cold-rolled steel plate and galvanized steel plate, coated (roll coated) or composite organic film (PVC film, etc.) after surface chemical treatment, and then baked and cured. Some people also call this product "pre roll coated color steel plate" and "plastic color steel plate".

BAI-OTT Color Coated Sheets Conveyor Hood Coveris made of color steel plate. The color steel plate coating is made of cold-rolled steel plate and galvanized steel plate, coated (roll coated) or composite organic film (PVC film, etc.) after surface chemical treatment, and then baked and cured. Some people also call this product "pre roll coated color steel plate" and "plastic color steel plate".

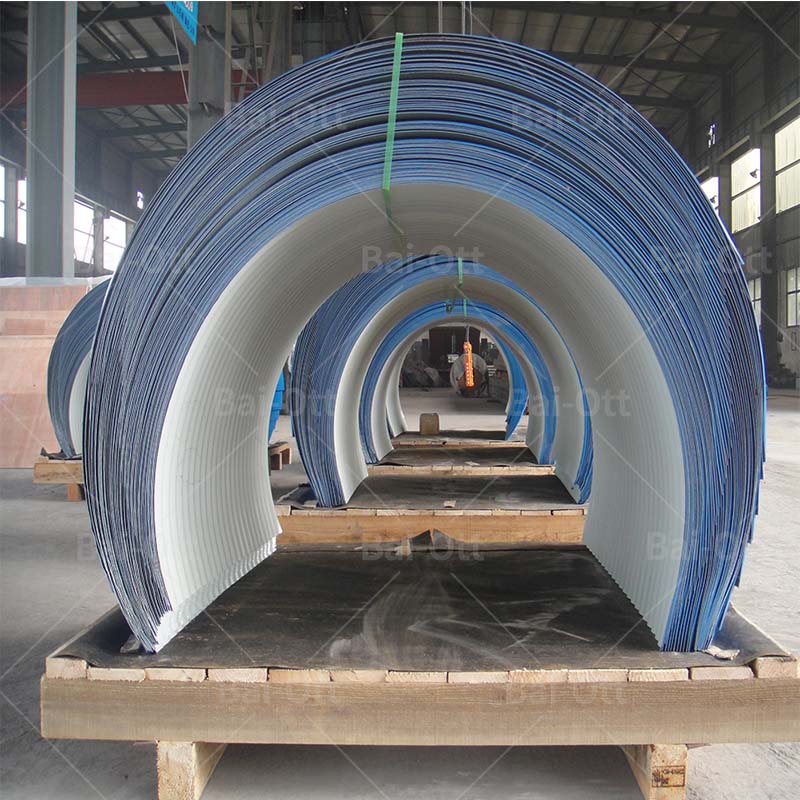

Conveyor Hood Cover cover is also known as Conveyor Hood Cover cover, color steel Conveyor Hood Cover cover, conveyor Conveyor Hood Cover cover, conveyor dust cover, belt conveyor Conveyor Hood Cover cover, etc. The Conveyor Hood Cover is widely used in power plants, cement plants, steel plants, chemical plants, coal plants, ports, docks, mining enterprises, etc.

The Conveyor Hood Cover plays a great role in the goods and environment. When the goods are transported, it can reduce the loss and waste of goods, make the conveyor belt safer and more reliable in the transportation process, and secondly prolong the service life of the conveyor.

The Conveyor Hood Cover has fixed type, open type and belt observation window type, which can clearly see whether the goods are in the transmission process and whether the conveyor belt operates normally. There is also a deviation cover, which plays the role of rain prevention and dust prevention for the conveyor with deviation switch.The main colors of Conveyor Hood Cover are sea blue, white gray, red, etc.

Advantage

Among the four forms of conveyor Conveyor Hood Covers, the fixed cover and open close cover are made of galvanized corrugated steel plate or color coated steel plate. Generally, 9 fixed covers and 1 open close cover are set in every 10 cover positions, or the two covers can be arranged alternately. During installation, press the opening and closing cover on the left and right adjacent fixed covers, and its overlapping length is one wave distance or two wave distances. Pay attention to place the hinged side of the opening and closing cover on the non passing side of the conveyor, and the side with latch on the passing side of the conveyor.

The frame used to fix the conveyor cover is connecting angle steel or Z-shaped steel, and its length is equal to the installation length of the conveyor cover. Weld the connecting angle steel or Z-shaped steel on the channel steel or small angle steel on both sides of the conveyor frame. If the support angle steel needs to be installed, first weld the support angle steel on both sides of the frame, and then weld the connecting angle steel or Z-shaped steel on the support angle steel.

Install the Conveyor Hood Cover in a "product" shape from one end to the other end of the frame. During installation, no one is allowed to stand on the Conveyor Hood Cover, and do not hit or knock it with force.

Fix the Conveyor Hood Cover on the connecting angle steel or Z-shaped steel with self tapping screws, with at least 4 fixing points for each piece.

One observation Conveyor Hood Cover can also be installed every 10 pieces to facilitate maintenance and inspection.

The folding point cover is only used at the folding point of the convex arc section of the conveyor, while the deviation switch cover is specially set to cover the deviation switch. Both are covered on the fixed cover.

Specifications

The color steel Conveyor Hood Cover prevents the color steel plate from rolling into a circular arc after cold rolling with wavy grain, and is installed on the conveyor to protect the transportation machinery and equipment, increase the service life of the equipment, reduce the maintenance cost, improve the economic benefit, and prevent the spread of dust during material transportation and environmental pollution. In addition, it can also protect the equipment from the influence of positive functions such as sun and rain, anti weathering, noise reduction and conveyor belt aging. It has the advantages of simple installation, low price and great economic and social benefits.

The production process of the Conveyor Hood Cover includes tray, upper part, pressure, cutting, pressure arc, height adjustment, packaging and other steps.

Color steel Conveyor Hood Cover manufacturers do not prepare spot goods, and the delivery period is generally 3-5 days.

Installation instructions:

1. Check whether the spare parts are complete during installation.

2. If it is arranged irregularly according to the installation sequence

3. Please be careful not to stand on it during installation to prevent on-site staff from being injured.

4. When installing color steel rainproof film, please pay attention not to rely on the mechanical equipment of internal machines.