Steel Plate Corrugated Hood Covers Conveyor

Brand: BAI-OTT or OEM

Feature: Abrasion and impact resistance

Size: Available

Material: Q235+Stainless steel

Sample: Provide

MOQ: 100 Meters

Sample: Provide

Product Inspection:Available

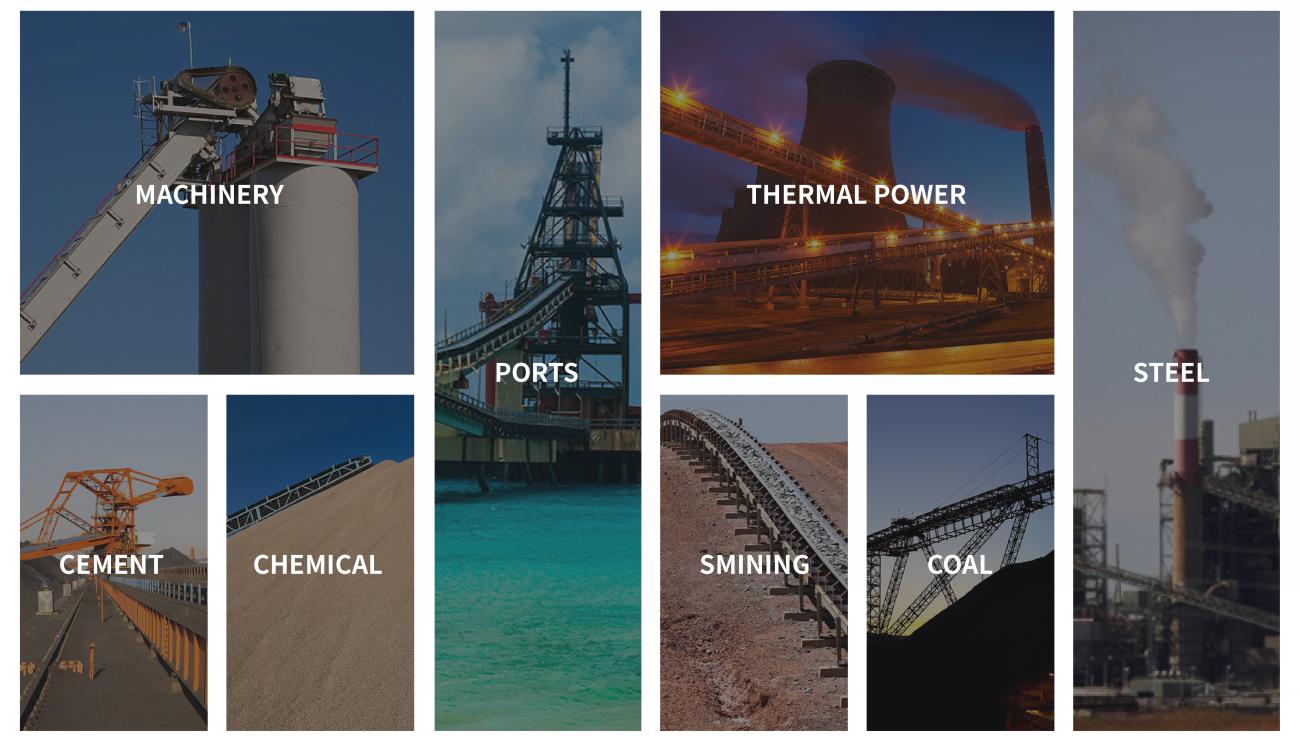

Application: Coal mines, Cement plants, Steel plants, Power plants and other factories

Lead time:Ready to ship in stock

View more Conveyor Hood Covers from BAI-OTT

Description

The Steel Plate Corrugated Hood Covers Conveyor is mainly used to prevent dust, while the outdoor protective cover is mainly used to protect the machine from working normally in various harsh natural environments (such as rain, snow, low temperature, high temperature, etc.). Therefore, the outdoor all-weather protective cover not only has a strict sealing structure. It also has many functions, such as wiper, spraying, heating and cooling. Therefore, the price of outdoor Conveyor Hood Cover is much higher than that of indoor protective cover. It should be noted that since the temperature in some areas varies little in four seasons and is within the working temperature, ordinary outdoor protective covers without constant temperature function can be selected to reduce the cost. When installing the Conveyor Hood Cover, weld the Z-shaped steel (rectangular pipe) on the top of the frame (side of the frame) and install the Conveyor Hood Cover from one end of the frame to the other end. During installation, no one is allowed to stand on the Conveyor Hood Cover and do not hit or knock with force. During installation, lap one or two corrugations with the size of 890mm or 860mm, and install one opening cover every 10 pieces (convenient for maintenance or viewing). Fix the Conveyor Hood Cover on the Z-shaped steel (rectangular pipe) with self tapping screws, with at least 4 fixing points for each piece.

The Steel Plate Corrugated Hood Covers Conveyor has light weight, beautiful appearance and good performance, and can be processed directly. It provides a new raw material for construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry and mining industry, and has a good effect of replacing wood with steel, construction, energy conservation and pollution prevention. Special insulating paperboard cloth (resistant to coolant, grinding wheel foam and iron filings) is formed by high-frequency heat sealing with foreign technology. This kind of shield has the characteristics of not afraid of stepping on feet, no deformation caused by hard objects, long service life, good sealing and light operation. The shield has long stroke, small compression and the ratio of length is 1:10. It is a form of folding shield, which can make up for the problems that can not be solved by other shields. Generally, this method is more reasonable when the total length of the belt conveyor Conveyor Hood Cover is short or the belt conveyor Conveyor Hood Cover operates in two directions. The reason is that the shorter belt conveyor Conveyor Hood Cover is easy to deviate and not easy to adjust. The Conveyor Hood Cover of long belt conveyor should not use this method, because the use of self-aligning idler group will affect the service life of the belt.

Advantage

Outstanding anti-skid characteristics: the anti-skid treatment is carried out in the manufacturing process, and the anti-skid characteristics far exceed the general different metal covers, wood covers, plastic covers, etc.

Good sealing characteristics and high stability. Compared with the metal cover with poor performance and the wood cover with poor material, the rain proof cover of this material has many characteristics, such as good sealing, non-conductive, heat transfer and so on.

Strong flame retardancy: the product has strong flame retardancy, no combustion and no danger.

Anti aging and excellent performance: the product has strong anti-aging performance, easy corrosion of materials and good performance.

Long service life and high economic benefits. Generally speaking, the service life of aluminum Conveyor Hood Cover is about 5 years and that of wood is about 3 years.

Specifications

The Steel Plate Corrugated Hood Covers Conveyor prevents the color steel plate from rolling into a circular arc after cold rolling with wavy grain, and is installed on the conveyor to protect the transportation machinery and equipment, increase the service life of the equipment, reduce the maintenance cost, improve the economic benefit, and prevent the spread of dust during material transportation and environmental pollution. In addition, it can also protect the equipment from the influence of positive functions such as sun and rain, anti weathering, noise reduction and conveyor belt aging. It has the advantages of simple installation, low price and great economic and social benefits.

The production process of the Steel Plate Corrugated Hood Covers Conveyor includes tray, upper part, pressure, cutting, pressure arc, height adjustment, packaging and other steps.

Steel Plate Corrugated Hood Covers Conveyor manufacturers do not prepare spot goods, and the delivery period is generally 3-5 days.

Installation instructions:

1. Check whether the spare parts are complete during installation.

2. If it is arranged irregularly according to the installation sequence

3. Please be careful not to stand on it during installation to prevent on-site staff from being injured.

4. When installing color steel rainproof film, please pay attention not to rely on the mechanical equipment of internal machines.