What is the belt conveyor return washing cleaning device

1 Introduction

With the acceleration of industrial upgrading, the state attaches more importance to the technological innovation and environmental protection of inland river ports. The traditional cleaning method of bulk cargo port belt conveyor is to use the cleaner installed in the unloading roller of the belt conveyor head drum, and with the screw stick and comb roller cleaning the material particles remaining on the working surface of the return conveyor belt. Through actual use, found that the traditional sweeper cleaning effect is poor, cannot viscous small particle materials for cleaning, so viscous material bonding on the return conveyor belt, in operation process, roller compaction, accumulated on the conveyor belt and stick and rotational component cleaning difficulties, reduce the operation efficiency and service life of belt conveyor, can not meet the requirement of the increase more material especially the use of food .

2 Design of belt backwash cleaning device

2.1 Design Parameters

Before the manufacture of the backwash cleaning device, the material characteristics of the goods and the basic parameters of the belt conveyor should be determined to determine the material, size and protection grade of the scraper, nozzle, box body and electrical components.

2.2 Structural Design

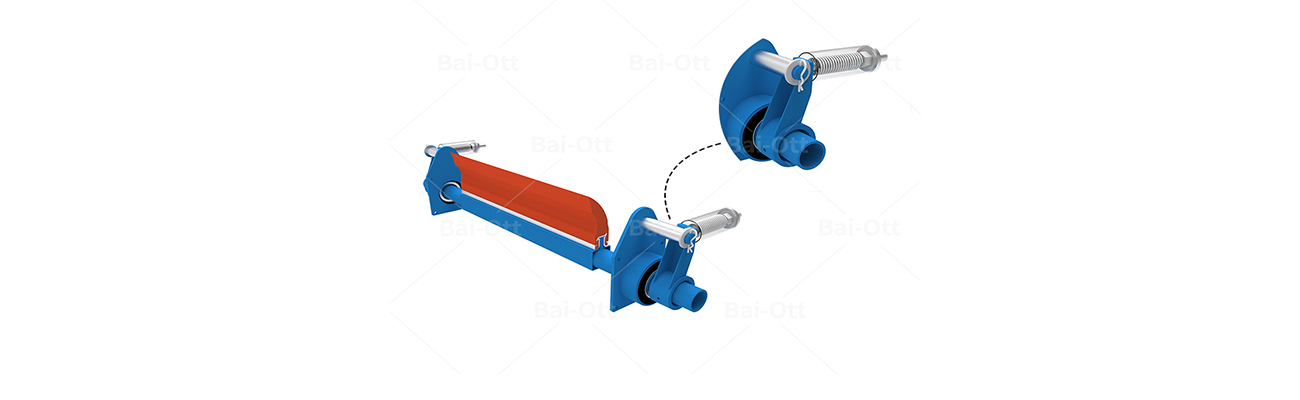

The backwash cleaning device is mainly composed of an integrated control supply system (including control system, gas supply equipment, water supply equipment), the main body of the cleaning box, pipe accessories, sewage pipes, etc. The backwash cleaning device is arranged in primary water spray, primary belt cleaner, second water cleaning, primary air drying system; The secondary cleaner and water cleaner are equipped with manually adjustable tensioning device; The upper part of the device is a cleaning and air drying system, and the lower part is a receiving hopper. Cleaning water pipes are arranged around the receiving hopper. The device effectively combines the characteristics of water, wind and mechanical sweeper, and thoroughly cleans the conveyor belt by wetting, dissolving, impacting, scraping, erasing and drying the conveyor belt of adhesive materials.

2.3 Working Principles

The backwash cleaning device blows the material attached to the conveyor belt in advance through the high-pressure linear water column ejected by the nozzle. After the material loosens and softens, the automatic lifting mechanism with built-in air bag lifts the sweeper to remove the material. During the cleaning process, the conveyor belt is tensioned by the flat support bar to ensure the smooth operation of the conveyor belt. After cleaning and washing the conveyor belt, the dewatering and air drying system starts to work to remove moisture on the conveyor belt, ensure that the surface of the conveyor belt is dry after washing, and avoid secondary pollution of the belt conveyor. The cleaning device is equipped with an external electric control box, which can be integrated into the central control system through programmable controller to realize remote chain control. The cleaning time can be flexibly set according to the pollution degree of the belt conveyor on site. When the belt conveyor is not in the cleaning state, the automatic lifting device of the built-in air bag mechanism of the return washing cleaning device can make the belt scraper blades break away from the conveyor belt at any time and end the cleaning.

The backwash cleaning device should be installed within the range of 5 000 mm behind the belt conveyor head roller, as close as possible to the head of the conveyor, to ensure that the belt conveyor will be timely and effective cleaning at the beginning of the return journey, and minimize the pollution of the rear supporting wheel and roller. The belt conveyor back to the ground distance shall not be less than 600 mm, to ensure that the cleaning device has enough installation space. In the place where the backwash cleaning device is installed, there should be a water source with water quality meeting the requirements within the range of 3 000 mm to avoid the blockage of the built-in nozzle; Sewage is collected to the sewage treatment system in the plant through the reserved sewage hole through the sewage pipe network.

3 Application Effect

The backwash cleaning device was put into use in the loading and unloading process equipment system project of a wharf berth transformation project. The spray system set in the device can effectively soften the material, remove the stains on the conveyor belt more thoroughly, and eliminate the material accumulation at the junction of the cleaner blade and the return conveyor belt. Through water lubrication, the friction between blade and conveyor belt is reduced, and the service life of scraper and belt conveyor is prolonged. The conveyor belt is dried before leaving the return washing cleaning device to ensure the dry cleaning of the conveyor belt and avoid the secondary pollution of the conveyor. The backwash cleaning device is used together with the traditional cleaner to ensure the deep cleaning of the belt conveyor. In the actual application of the project, the same conveyor is used to transport three kinds of logistics such as grain, chemical fertilizer and wood chip, which greatly improves the utilization rate of the overall equipment and achieves good economic benefits. In terms of environmental benefits, the sewage generated in the cleaning process is collected to the plant sewage treatment system for centralized treatment through the pipe network, which eliminates the phenomenon of falling along the conveyor belt caused by the material and reduces the dust pollution along the conveyor belt.

4 Conclusion

According to the field application experience, the return washing cleaning device has a good use effect, thoroughly cleans the return conveyor belt, and realizes the diversified use of multi-cargo bulk port belt conveyor in inland rivers. It can be popularized and applied in other projects under the condition of combining the local actual situation.