How to design the conveyor belt scraper

Introduction: A belt conveyor scraper is a device used to remove material from the surface of a belt conveyor.

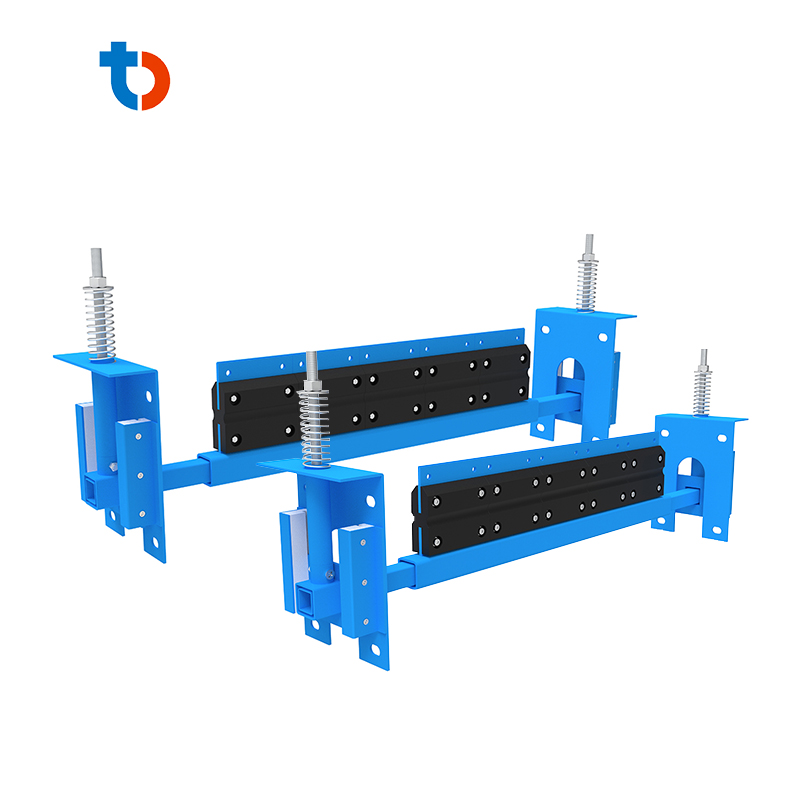

Belts conveyors are an essential necessary cleaning system equipment in many industrial and commercial settings. They are used to remove materials or products from one location to another location. The surface of a belt can become dirty or coated with material that needs to be removed. This is where a belt conveyor scraper comes in handy. A scraper or belt cleaner is a device that is closely attached to the surface of a belt and is used to remove transportation conveying material from the belt. Belt cleaner comes in a variety of shapes and sizes, depending on the type of material that needs to be removed. They can be made from metal, plastic, or rubber, and can be mounted on either the top or bottom of the belt conveyor. A belt conveyor scraper is used to remove dirt and other material from the surface of a conveyor belt. This is done by scraping away at the material with a flat edge, or puck, that has been designed to fit the surface of the conveyor belt.

Design: Conveyor belt scraper blades are typically made of metal, plastic, or rubber and are attached to the end of a scraper arm.

Conveyor belt scraper blades are typically made of metal, plastic, or rubber and are attached to the conveyor belt to clean off any built-up materials. The type of material that the blade is made of can depend on the type of material that is being conveyed. For example, if the conveyor belt is moving wood materials, a metal blade may be better suited than a PU blade. Scraper blades can be made out of any material. The blade materials are not only aimed at cleaning up the residual materials on the conveyor belt but also need to have the advantage of protecting the conveyor belt surfaces when scrapping the materials during conveyor operation. PU belt scraper blades and Alloy belt scraper blades are most common and are usually used in different factories such as mining, power plant, and harbor... because they allow for easy movement of the material on the conveyor belt.

There are a variety of scraper blades available on the market, each designed for a specific purpose in different working environments and applications. Alloy blades are typically used for heavy-duty scrapings like power plant or stone mining, while PU blades are better suited for delicate surfaces to clean the materials such as cement or sand, or metal because PU can better touch the belt to keep a better cleaning effect. No matter what type of blade you choose, it is important to make sure that it is securely attached to the end of the belt cleaner frame.

How to choose the right conveyor belt cleaner:

1. Confirm where the cleaner will be installed on. You need to decide the type of your application environment or conveyor working situation. PU materials need to confirm the transportation materials' temperature and chemical property.

2. Measure the size of the conveyor belt width to confirm the cleaner size.

3. Decides the belt cleaner strength is the conveyor belt's working speed and strength. You can choose heavy-duty type for speed beyond 3.5m/S, normal type if under 3.5m/S.

4. Supply your conveyor frame width so that can confirm the belt cleaner frame.

Operation: The scraper blades scrape the material from the conveyor belt while the conveyor is in motion.

Operation of the scraper blades scraping the material from the conveyor belt while the conveyor is in motion provides an efficient and reliable way to clean the belt. The blades are adjustable to ensure that they can clean any material from the belt, and they are also replaceable when necessary. This system helps keep your conveyor running smoothly and prevents build-up on the belt that could cause problems further down the line.

Installing the belt scraper blades in the correct position on the conveyor is important for maintaining a clean surface. Incorrect installation can cause the blades to wear down more quickly and create a mess. The blades should be positioned so that they scrape the entire width of the conveyor belt. With the belts properly installed on the conveyor, they should be adjusted to provide comfortable and even friction when the conveyor is in motion. The belt tensioning system allows operators to adjust the belt tension and speed of the conveyor belt without having to physically adjust the gears. A belt running at 800 ft/min (50 m/min) can be adjusted for tensioning up to 450-500 pounds per inch, or 50-60 kilograms per centimeter.

Conclusion: A belt conveyor scraper is an important piece of equipment for any conveyor system.

Belt conveyor scraper design is a critical factor in the success of belt conveyor systems. Proper belt scraper design can minimize wear on the conveyor system, increase production, and improve overall machine performance. The design must take into account the width, spacing, and type of belt being used as well as the size and shape of the scraper blade. In this article, we discuss some key factors to consider when designing a belt scraper for use with a conveyor system.