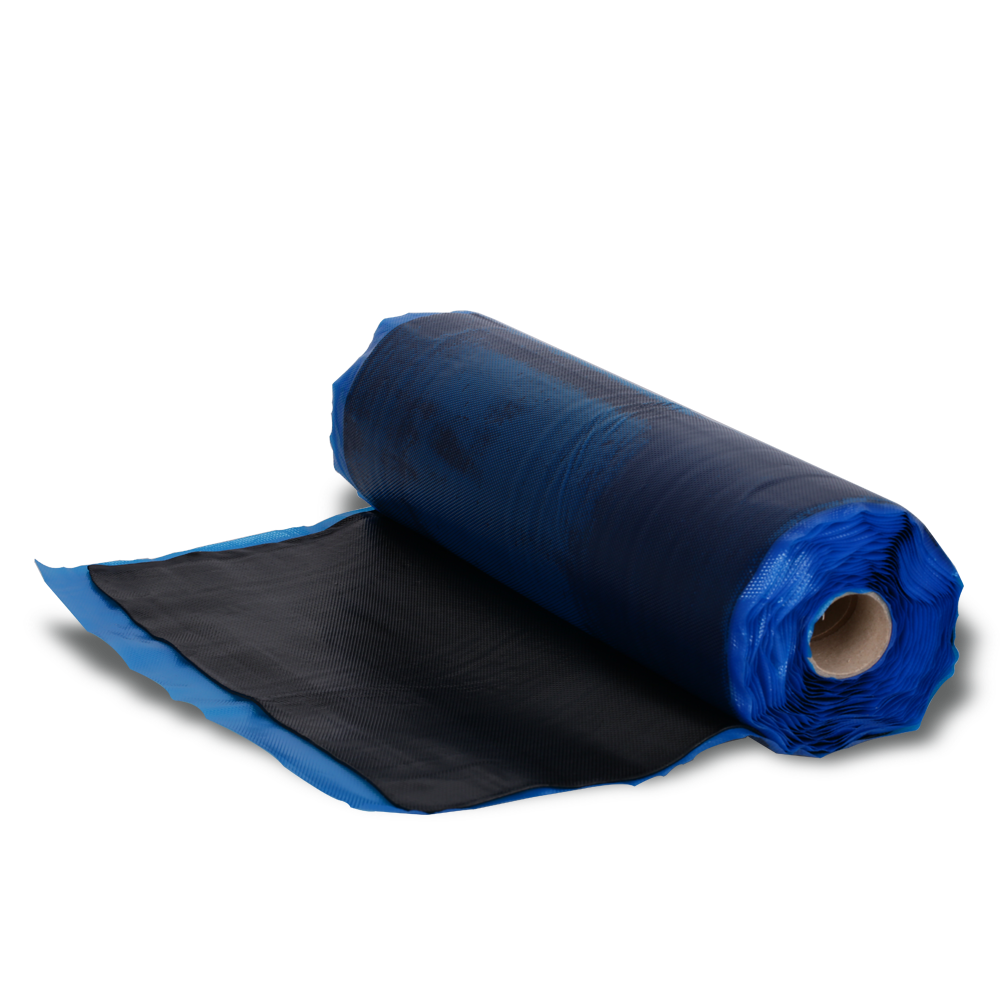

Repair materials of conveyor belt--uncured tie gum and uncured cover rubber

The uncured tie gum produced by Bai-Ott is the core layer padding material used for the hot repair or hot vulcanizing joint of the conveyor belt. Uncured tie gum replaces the rubber between the fabric layer and the steel cord that refilled and vulcanized to obtain strong adhesive force and adhesion force, which makes the whole belt flat and tight after repair and joint so as to achieve a good belt tension effect.

The type of uncured tie gum depends on the type and the specifications of belt. The corresponding specification of uncured tie gum can shorten the completion period and improve the quality of repaired joints to a certain extent.

According to the type of belt used, uncured tie gum can be divided into layered uncured tie gum and steel cord uncured tie gum. PVC/PVG conveyor belt only needs cover rubber not uncured tie gum.

Apart from a definite difference in material properties, the uncured tie gum used for layered belt and steel belt has the same specifications such as width, thickness and weight, which can be mainly divided into five types: 1/2/3/4/5mm thick by 500mm wide, with a weight of 10kg per roll, and 0.8mm tie gum is also commonly used.

Using the corresponding specification of uncured tie gum can reduce the number of layers of tie gum. The laying of multi-layer tie gum needs to brush hot vulcanizing cement in the middle of each layer of rubber as a binder to eliminate air bubbles. The increase of construction steps also increases the unstable factors, which is more influenced by the experience and technology of workers. Too thick rubber will increase the joint thickness and deteriorate the bending flexibility and reduce the passability of roller and sweeper.

Therefore, it is necessary to select the corresponding thickness and specification of tie gum according to the material and model of the belt to be repaired or jointed.

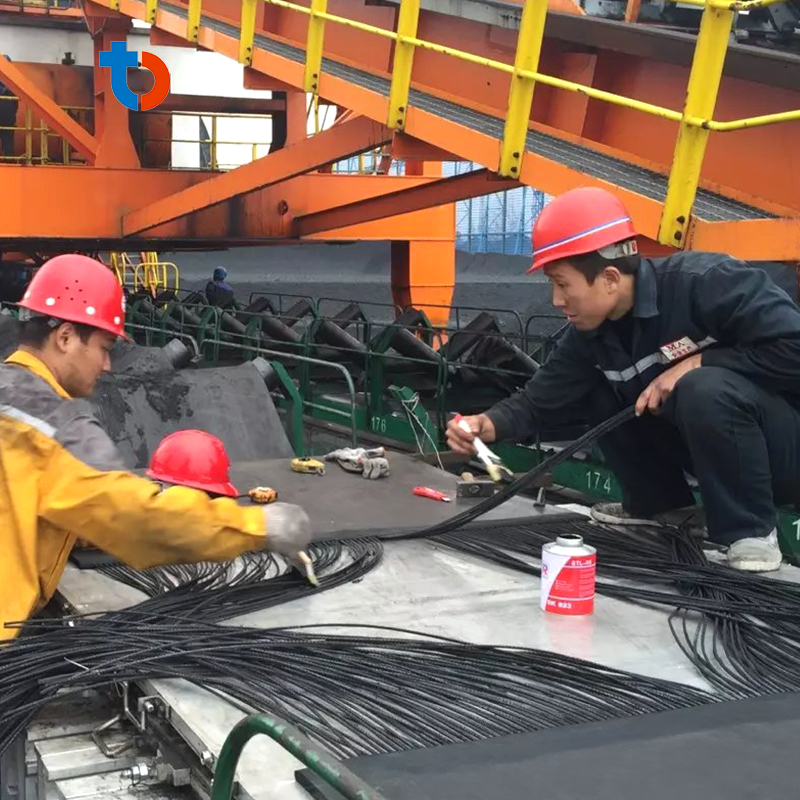

Matters needing attention and technical process of tie gum and cover rubber (field operation case)

Step one. Preparations

1. Select a suitable place (power supply, excellent ventilation effect) and then unfold each roll of belt to the required bonding position.

2. Inspection of vulcanization equipment and tools, check whether the joint tools required for vulcanizing are self-contained.

Step two. the joint layered processing and bonding.

1. Step-by-step treatment of the belt. The exposed surface is circuitously polished with an angle grinder and a tungsten buffing disc after the treatment is completed.

2. Clean the polished surface, and evenly brush the hot vulcanizing cement on the polished part.

3. Cover the brushed belt joint with uncured tie gum and uncured cover rubber and spread it as far as possible, then cut the uncured cover rubber surface with a knife to avoid swelling.

4.With the help of the vulcanizing press, the joint is heated and pressurized,the vulcanizing press stop heating after the time (when the temperature reaches 145℃, it needs to be kept at a constant temperature for 40-45 minutes).

5. Dismantle the vulcanizing press after it is cooled down, and trim the nylon belt joint with a rubber knife. Then vulcanization is completed.