Light-Duty Rubber Conveyor Impact Buffer Strip

Brand: BAI-OTT or OEM

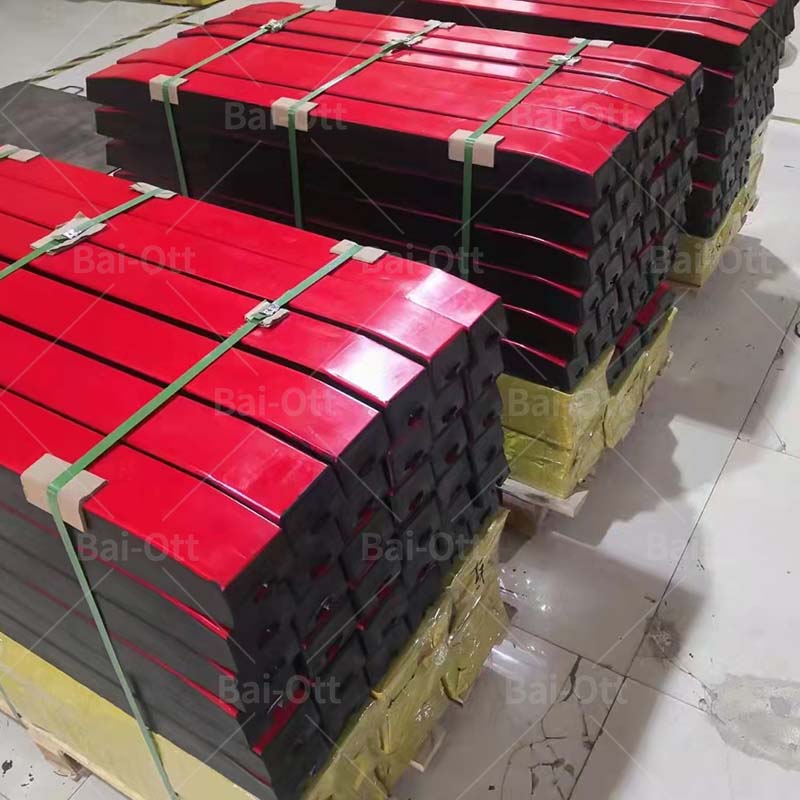

Feature: High elastic+Adjustable+High quality

Shape: Custom

Material: PE+Rubber+Steel Bolt

Sample: Provide

Product Inspection:Available

MOQ: 1 Set

Lead time:Ready to ship in stock

View more Impact Beds&Bars from BAI-OTT

Description

Light-Duty Rubber Conveyor Impact Buffer Strip

The Impact Bed is composed of buffer strips, and the buffer strips mainly use excellent high elastic special rubber layer to fully and effectively absorb the impact force when the material falls, greatly reduce the impact on the conveyor belt when the material falls, and truly improve the stress condition of the blanking point. The use of the buffer bed ensures the face-to-face contact and uniform stress of the conveyor belt, effectively prevents the longitudinal tear of the belt caused by the breakage and falling off of the idler, and greatly reduces the probability of longitudinal tear after the belt is penetrated by sharp tools or sharp materials. It can be processed and produced according to the requirements of customers and drawings. At the beginning of the design of the buffer bed, the purpose is to fully protect the conveyor belt and prolong its service life when blanking and buffering.

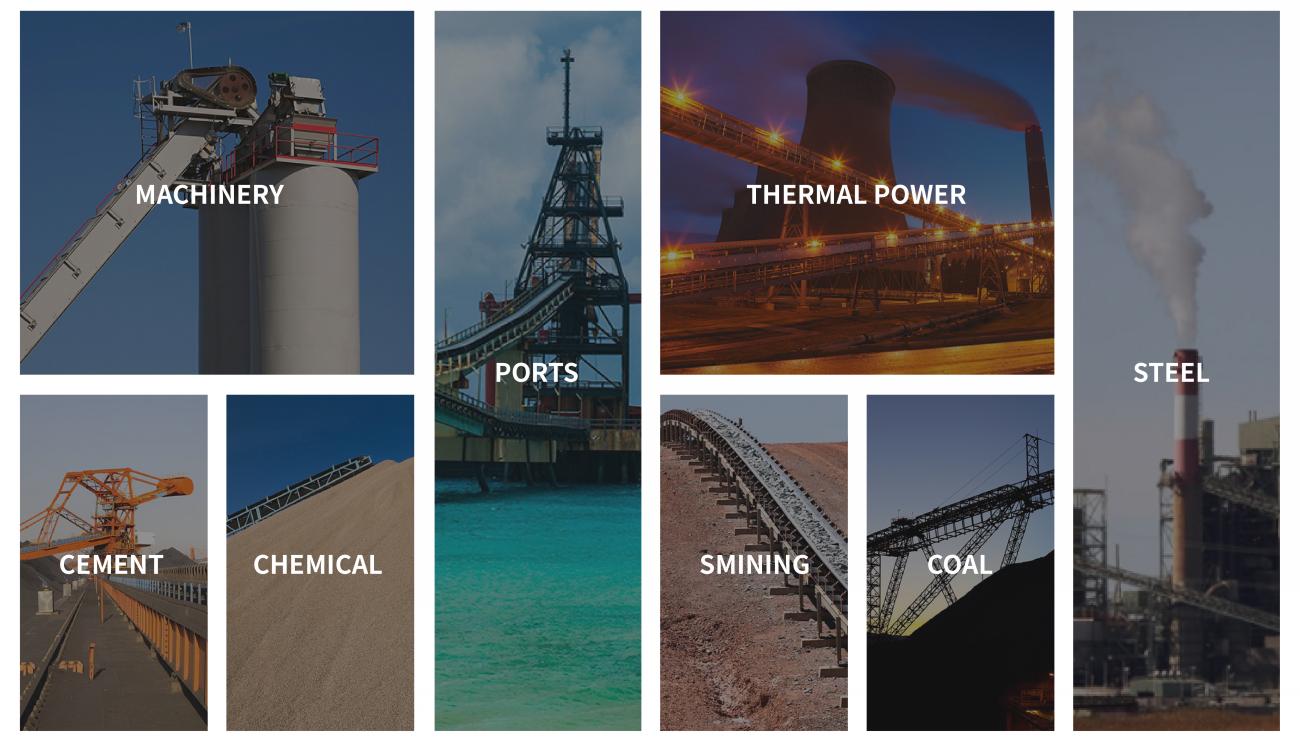

Our company is a professional buffer bed manufacturer and has a systematic buffer bed database. According to different bandwidth, different industrial and mining conditions and different installation positions, our company has fine classification. According to our many years of design and production experience, it is found that the belt conveyor at more than 90% of the buffer bed installation positions in China is different from the national standard, This also determines that the one-to-one design must be carefully adopted in the design of the buffer bed. However, if the customer determines that the belt conveyor installed on the buffer bed is the national standard, you only need to inform its relevant corresponding number, and our company will provide you with standardized production.

Advantage

No moving parts, reduce daily maintenance costs.

Loose and loose materials, and reduce the average drop and damage of the belt.

Absorb impact energy.

The inclined chamfer can smoothly guide the belt to avoid tripping.

Suitable for various belt widths and angles.

Specifications

When the buffer strip is impacted, it plays a good buffering role mainly through elastic materials and its own physical elasticity. Therefore, the rubber elasticity must meet certain conditions. Internationally, the rubber elasticity of the buffer strip is about 55 degrees shore hardness, and the rubber must also have certain corrosion resistance. If the rubber is used underground, it must be treated flame retardant rubber, It also has certain tear resistance, tensile strength, elongation at break, adhesive strength of rubber non-metallic profiles, etc. Therefore, when selecting manufacturers, it is best to choose manufacturers with the ability of inspection and experimental equipment. Through comparative experiments with domestic manufacturers, it is found that some enterprises publicize good performance indicators, but the most basic rubber hardness has not been reached. After testing, the hardness of some manufacturers is about 70 degrees, which can not play the role of material buffer at all.

1. Buffer of high drop blanking point.

2. Blanking buffer with uneven size.

3. High density blanking buffer.

4. Improve the sealing of blanking area (prevent overflow).

The buffer bed is an alternative tool for the buffer idler. It can absorb the impact, prevent the belt from tearing, slow down the impact and damage of materials to the belt, avoid the tear and scratch of sharp objects to the belt, and prevent the overflow and scattering of materials.

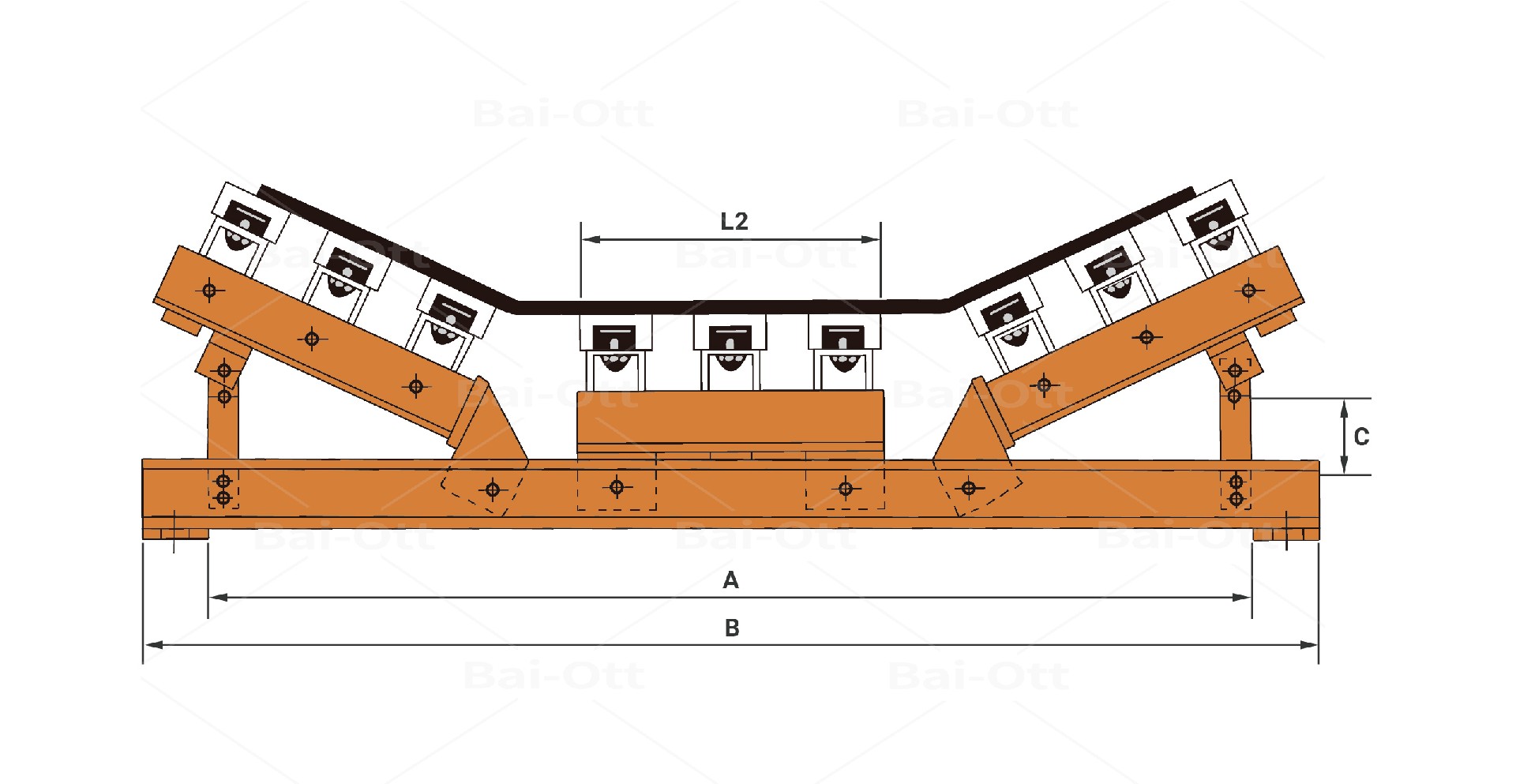

| Order NO. | Belt width/mm | Impact bar/mm | A/mm | B/mm | C/mm | L2/mm | Imapact bar | Weight/kg | ||||

| RIT-IB-650 | 650 | 1220 | 890 | 950 | 185 | 240 | 2 | 2 | 2 | 9 | 11 | 16 |

| RIT-IB-800 | 800 | 1220 | 1090 | 1150 | 188 | 270 | 2 | 2 | 2 | |||

| RIT-IB-1000 | 1000 | 1220 | 1290 | 1350 | 216 | 370 | 3 | 3 | 3 | |||

| RIT-IB-1200 | 1200 | 1220 | 1540 | 1600 | 246 | 420 | 3 | 3 | 3 | |||

| RIT-IB-1400 | 1400 | 1400 | 1750 | 1810 | 251 | 500 | 4 | 4 | 4 | 10.5 | 12.5 | 18.5 |

| RIT-IB-1600 | 1600 | 1400 | 1990 | 2050 | 296 | 580 | 4 | 4 | 4 | |||

| RIT-IB-1800 | 1800 | 1524 | 2210 | 2280 | 315 | 710 | 5 | 5 | 5 | 11.5 | 14 | 20 |

| RIT-IB-2000 | 2000 | 1524 | 2420 | 2500 | 342 | 720 | 5 | 5 | 5 | |||