Medium ez High Molecular Conveyor Impact Slider Bed

Brand: BAI-OTT or OEM

Feature: High elastic+Adjustable+Abrasion Resistant

Shape: Custom

Material: PE+Rubber+Steel Bolt

Sample: Provide

Product Inspection:Available

MOQ: 1 Set

Lead time:Ready to ship in stock

View more Impact Beds&Bars from BAI-OTT

Description

Product overview

Medium High Molecular Conveyor Bed is used in the blanking section of belt conveyor and is an alternative product of buffer supporting mixing. The main function is to better support and protect the conveyor belt, and reliably and effectively avoid the impact damage and splitting of falling materials on the conveyor belt. The buffer strip is vulcanized from high molecular polyethylene plate and high elastic rubber. The high elastic rubber buffer bed absorbs the impact energy of falling materials on the conveyor belt and conveyor frame; The high-strength metal skeleton can withstand the impact of large load. The polymer polyethylene plate on the surface has high impact strength and low friction coefficient, which can reduce the friction with the conveyor belt and is conducive to the normal operation of the conveyor. The buffer sliding strip has flame retardant and antistatic properties and is suitable for combustible gas environment. The utility model has the advantages of compact structure, convenient installation and maintenance, long service life and no damage to the adhesive tape and mechanical joints. It is a kind of conveying auxiliary equipment composed of buffer strip and support frame. It is a good product instead of buffer roller. Installed under the conveyor belt, it can help absorb and decompose the impact force on the conveyor belt when the materials fall, prevent the material splash caused by uneven force on the belt, improve the stress condition of the conveyor belt and prolong the service life of the belt, It is an environment-friendly blanking buffer device. Our company is a professional manufacturer of polymer buffer bed and buffer strip, which aims to think from the perspective of customers and provide customers with systematic services, such as buffer bed design, measurement and data analysis, buffer bed installation and commissioning, buffer bed maintenance and other services and technical consultation.

| Item | Parameter | Standard Type | High Elastic Type | Downhole Type | |

UHMWPE Part | Color | Blue | Blue | Black | |

| Tensile breaking strength | Mpa | 23 | 23 | 20 | |

| Elongation at break | % | 300 | 300 | 250 | |

| Hardness | Shore A | 60-70 | 60-70 | 65-75 | |

| Abrasion | cm3 | 0.053 | 0.053 | 0.08 | |

| Density | g/cm3 | 0.93-0.94 | 0.93-0.94 | 1.13 | |

High Elastic Rubber Part | Hardness | Shore A | 60-65 | 45-50 | 60-65 |

| Strength of Extension | Mpa | 19 | 19 | 19 | |

| Elongation at break | % | 400 | 400 | 400 | |

| Metal Part | Type | Aluminium Alloy | |||

Bond Strength | Bonding of PE&rubber | N/mm | ≥10 | ≥10 | ≥10 |

| Bonding of metal&rubber | N/mm | ≥10 | ≥10 | ≥10 | |

Advantage

Can withstand strong impact.

Quick and simple installation, easy inspection and replacement.

It is installed at the blanking point of the conveyor belt to prolong the service life of the belt.

The surface contact between the buffer strip and the conveyor belt effectively prevents damage to the conveyor belt

The conveyor belt is stressed evenly at the blanking port, which greatly reduces the daily repair and maintenance cost

Specifications

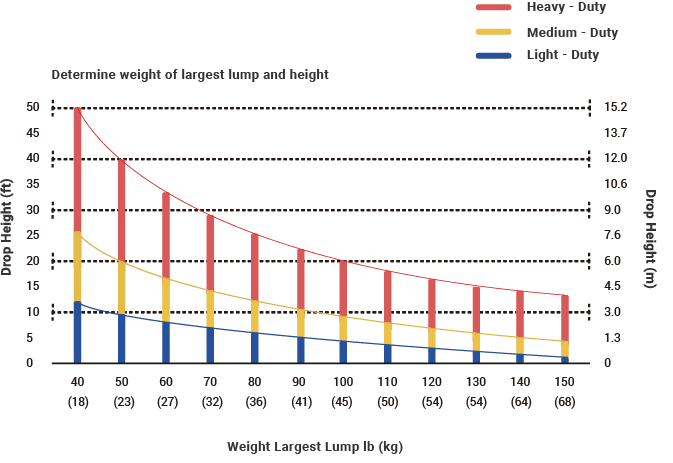

Factors affecting the use effect of Medium High Molecular Conveyor Bed:

1. Design of buffer bed and its impact resistance;

2. Quality of buffer strip;

3. Whether the material selection of polymer buffer bed support is reasonable and whether the welding is firm;

4. Whether the installation of buffer bed is applicable to the requirements of "triple buffer".

The use of the impact bed makes the belt stress uniform, better prevent the scattering and splashing of materials, reduce the adhesion of materials, reduce friction and better protect the belt. At present, the buffer bed has become an indispensable part of the belt conveyor. With its excellent buffer capacity, the buffer bed can effectively ensure the smooth operation of the belt conveyor and greatly reduce the impact of material falling. That is, it can effectively prevent the large-area scattering of materials and save the production cost. The so-called high molecular weight buffer bed is a buffer bed using high molecular weight buffer strips. The high molecular weight buffer bed of our company adopts real high molecular weight buffer strips, with surface molecular weights of up to 5 million and 9.2 million. The working environment is different. The polymer buffer bed is divided into ordinary buffer bed and underground flame-retardant buffer bed, which can adapt to any harsh working environment, ensure the smooth operation of your belt conveyor and save you the cost of belt conveyor maintenance.

The impact bed was used by the Germans in the last century, after long-term development, it has replaced the rhythm of the traditional buffer idler and is known as the protector of the belt conveyor. With the buffer bed, it can effectively prevent the damage to the belt and prolong the service life of the belt for many years. It is easy to install and maintain on site, and the angle can be adjusted. The left and right side beds can be placed horizontally, so that the whole set can slide into the installation from the side of the conveyor. The quotation of polymer buffer bed is quoted. The buffer strip can be replaced by one or one side. The buffer strip can be replaced by loosening the T-shaped bolt. The cushion support is made of Q235, which is solid and corrosion-resistant as a whole.

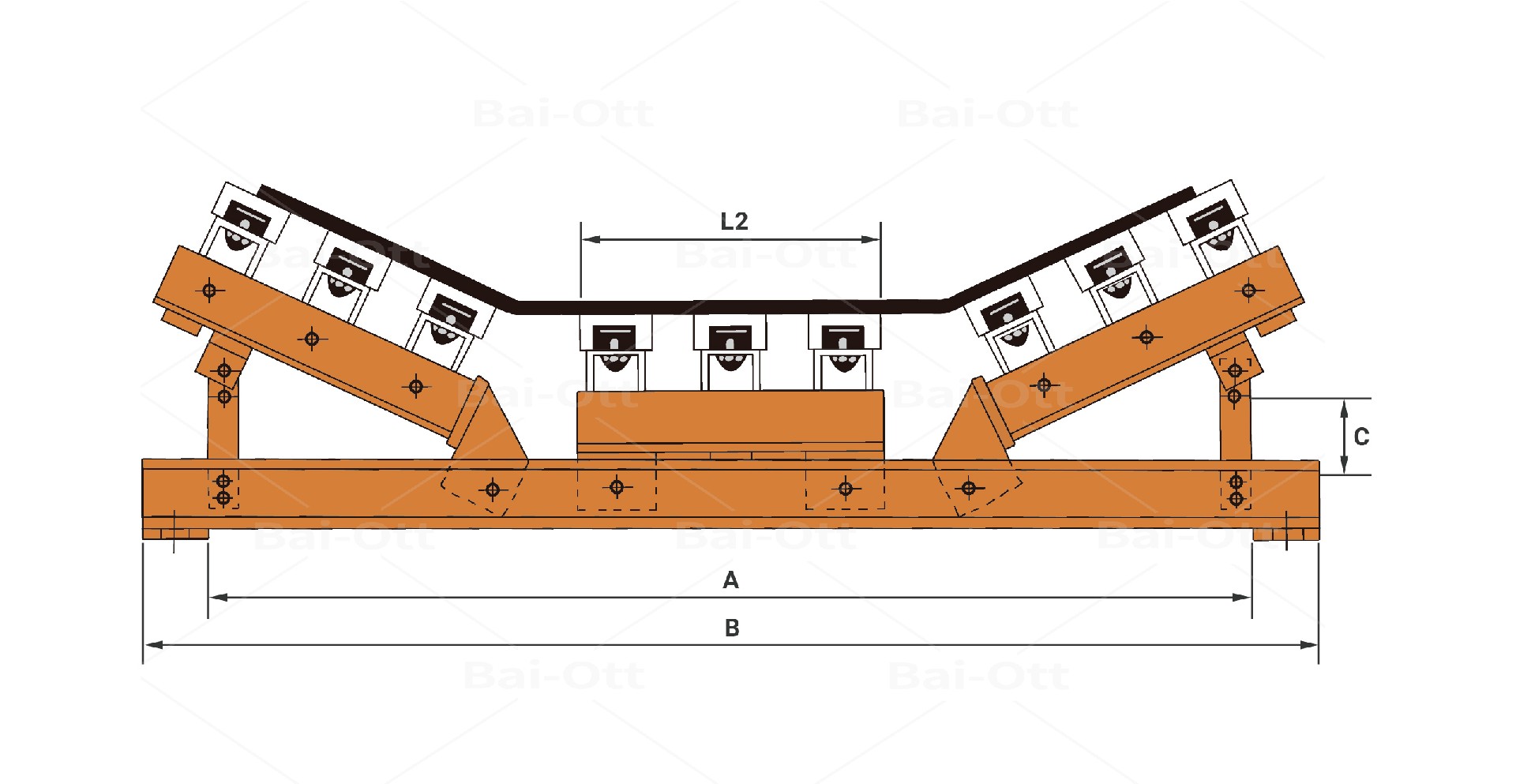

| Order NO. | Belt width/mm | Impact bar/mm | A/mm | B/mm | C/mm | L2/mm | Imapact bar | Weight/kg | ||||

| RIT-IB-650 | 650 | 1220 | 890 | 950 | 185 | 240 | 2 | 2 | 2 | 9 | 11 | 16 |

| RIT-IB-800 | 800 | 1220 | 1090 | 1150 | 188 | 270 | 2 | 2 | 2 | |||

| RIT-IB-1000 | 1000 | 1220 | 1290 | 1350 | 216 | 370 | 3 | 3 | 3 | |||

| RIT-IB-1200 | 1200 | 1220 | 1540 | 1600 | 246 | 420 | 3 | 3 | 3 | |||

| RIT-IB-1400 | 1400 | 1400 | 1750 | 1810 | 251 | 500 | 4 | 4 | 4 | 10.5 | 12.5 | 18.5 |

| RIT-IB-1600 | 1600 | 1400 | 1990 | 2050 | 296 | 580 | 4 | 4 | 4 | |||

| RIT-IB-1800 | 1800 | 1524 | 2210 | 2280 | 315 | 710 | 5 | 5 | 5 | 11.5 | 14 | 20 |

| RIT-IB-2000 | 2000 | 1524 | 2420 | 2500 | 342 | 720 | 5 | 5 | 5 | |||