Medium Fire-resistance Rubber Impact Slider Bed

Brand: BAI-OTT or OEM

Feature: High elastic+Adjustable+Fire-resistance

Shape: Custom

Material: PE+Rubber+Steel Bolt

Sample: Provide

Product Inspection:Available

MOQ: 1 Set

Lead time:Ready to ship in stock

View more Impact Beds&Bars from BAI-OTT

Description

Product overview

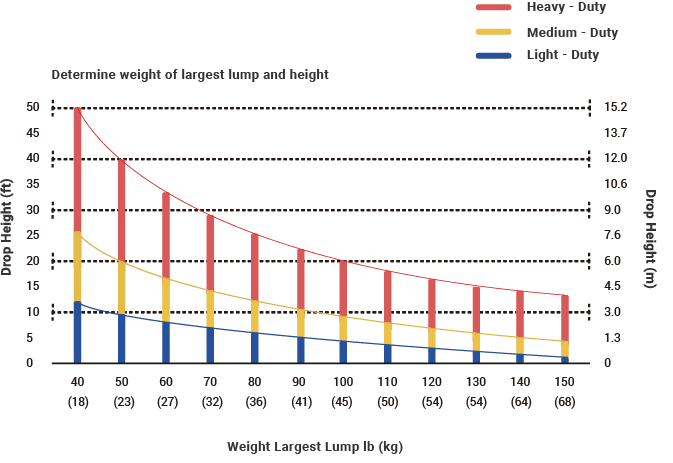

Medium Fire-resistance Impact Slider Bed is also known as flame retardant buffer sliding bed and flame retardant buffer supporting bed. The chute of the flame-retardant buffer bed is composed of flame-retardant buffer strips. The flame-retardant buffer strips are mainly made of excellent high elastic special rubber layer, which fully and effectively absorbs the impact force when the material falls, greatly reduces the impact on the conveyor belt when the material falls, and truly improves the stress condition of the falling point. The special UHMW high molecular polyethylene surface is adopted to reduce the friction coefficient between the conveyor belt and the flame-retardant buffer strip sliding strip to a low level and has good wear resistance. The chute of the flame-retardant buffer bed uses the face-to-face contact of the conveyor belt, with uniform stress, which effectively prevents the longitudinal tear of the belt caused by the breakage and falling off of the idler, and greatly reduces the probability of longitudinal tear after the belt is penetrated by sharp tools or sharp materials. The effective support design of the buffer bed ensures that the buffer bed can meet the use demand of impact force.

The impact bed is the key equipment commonly used in the conveying system. It is used under the guide chute of the belt conveyor and under the belt at the blanking point to cushion the impact of falling materials on the conveyor belt. The buffer bed, also known as the buffer chute, is in face-to-face contact with the conveyor belt, with uniform stress, so as to prevent material overflow and scattering, and greatly improve the service life of the conveyor belt. It slows down the impact and damage of materials on the conveyor belt and avoids the tearing, scratching and blanking of sharp objects on the belt. It is made of ultra-high molecular polyethylene with low friction coefficient and fixed on the steel support through high elastic rubber buffer. It reduces the wear of the conveyor belt by effectively supporting the conveyor belt and absorbing the impact of materials on the conveyor belt. The ingenious design of the buffer bed overturns the traditional thinking, makes the buffer strip in the blanking area contact with the surface of the conveyor belt, provides comprehensive support, effectively prevents the uneven stress on the conveyor belt during material transportation, and greatly reduces the maintenance and repair caused by the impact damage to the conveyor belt. The buffer bed maintains the tightness between the belt and the anti overflow skirt, and effectively eliminates the material splash and leakage caused by the impact deformation of the belt between adjacent buffer idlers.

| Item | Parameter | Standard Type | High Elastic Type | Downhole Type | |

UHMWPE Part | Color | Blue | Blue | Black | |

| Tensile breaking strength | Mpa | 23 | 23 | 20 | |

| Elongation at break | % | 300 | 300 | 250 | |

| Hardness | Shore A | 60-70 | 60-70 | 65-75 | |

| Abrasion | cm3 | 0.053 | 0.053 | 0.08 | |

| Density | g/cm3 | 0.93-0.94 | 0.93-0.94 | 1.13 | |

High Elastic Rubber Part | Hardness | Shore A | 60-65 | 45-50 | 60-65 |

| Strength of Extension | Mpa | 19 | 19 | 19 | |

| Elongation at break | % | 400 | 400 | 400 | |

| Metal Part | Type | Aluminium Alloy | |||

Bond Strength | Bonding of PE&rubber | N/mm | ≥10 | ≥10 | ≥10 |

| Bonding of metal&rubber | N/mm | ≥10 | ≥10 | ≥10 | |

Advantage

The surface contact between the flame-retardant buffer strip and the sliding strip of the conveyor belt effectively prevents the damage to the conveyor belt

The conveyor belt is stressed evenly at the blanking port, which greatly reduces the daily repair and maintenance cost

Effectively eliminate material splash and leakage caused by uneven stress of conveyor belt

The smooth surface of higher molecular weight polyethylene reduces the friction of the conveyor belt during operation

The arc design on the surface of polyethylene layer makes the conveyor belt run smoothly

The high elastic special rubber layer can absorb the impact force of materials to a great extent

All parts of the flame-retardant buffer strip and sliding strip are connected by thermal vulcanization process, which is compact and firm

The design of the bottom steel structure makes the disassembly and assembly convenient and fast

Specifications

The use of the buffer bed makes the belt stress uniform, better prevent the scattering and splashing of materials, reduce the adhesion of materials, reduce friction and better protect the belt. At present, the buffer bed has become an indispensable part of the belt conveyor. With its excellent buffer capacity, the buffer bed can effectively ensure the smooth operation of the belt conveyor and greatly reduce the impact of material falling. That is, it can effectively prevent the large-area scattering of materials and save the production cost. The so-called high molecular weight buffer bed is a buffer bed using high molecular weight buffer strips. The high molecular weight buffer bed of our company adopts real high molecular weight buffer strips, with surface molecular weights of up to 5 million and 9.2 million. The working environment is different. The polymer buffer bed is divided into ordinary buffer bed and underground flame-retardant buffer bed, which can adapt to any harsh working environment, ensure the smooth operation of your belt conveyor and save you the cost of belt conveyor maintenance.