Composite Wear-resistant Ceramic Liner

Brand: BAI-OTT or OEM

Bending Strength(Mpa): >280

Feature: Abrasion and impact resistance

Size: Available

Material: Ceramic+Rubber+Polyurethane

Sample: Provide

MOQ: 1 Square Meter

Lead time:Ready to ship in stock

View more Ceramic Lining from BAI-OTT

Description

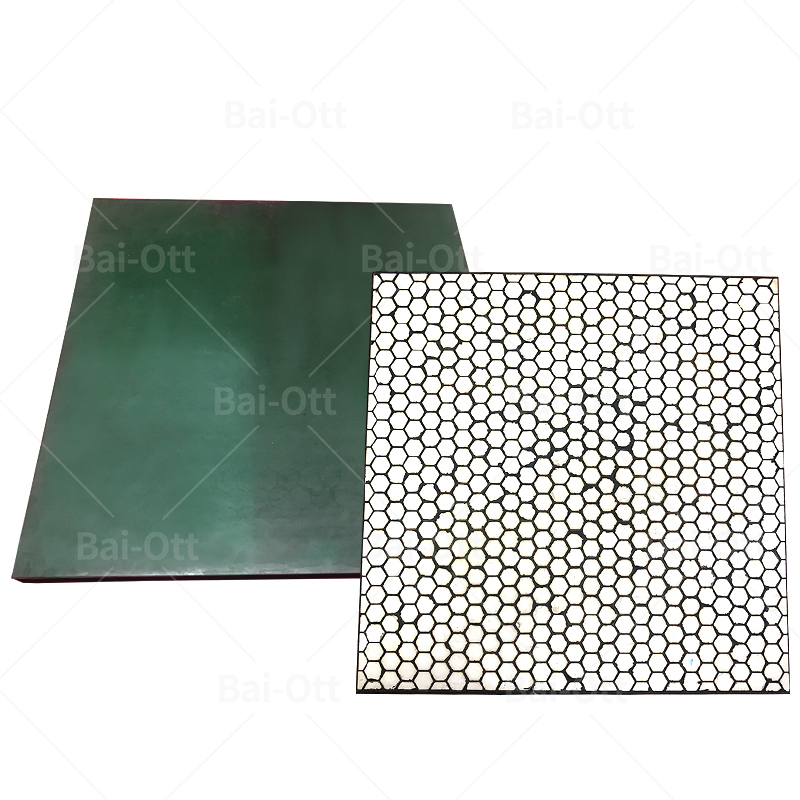

Composite Wear-resistant Ceramic Liner

The wear-resistant and impact resistant alumina ceramic liner produced by our company is a wear-resistant ceramic fired at 1700 ℃ with alumina as the main raw material. The Rockwell hardness HAR90 is only after the diamond. Far more than other wear-resistant materials.

Good impact resistance: ceramic and rubber are combined, and rubber plays a buffer role, which can effectively absorb the impact force. It can be used in occasions with large material particles, large drop and large impact force.Non stick material: it is used in the service environment with serious wear and adhesion. The ceramic surface is smooth, the resistance of materials passing through is small, and the materials are not bonded.The design is scientific and easy to install. The lining plate and equipment are connected with the equipment by welding and bolts, and will never fall off. Moreover, it can be cut and decomposed, can be twisted and assembled, has corrosion resistance, superior chemical performance and good stability.The lining plate is vulcanized as a whole, and the ceramic rubber steel plate will never delamination, so as to ensure the service life of the product. This technology is at the leading level in China.High temperature resistance: it can operate at 0 ℃ - 250 ℃ for a long time;Acid and alkali resistance: the rubber adopts a new formula of acid and alkali resistance rubber, which can resist weak acid and weak alkali;Anti falling off: ceramic rubber steel plate is vulcanized as a whole, and the combination is very firm; Each ceramic has a penetrating bolt passing through the bottom steel plate and is firmly welded with double safety;Wear resistance: alumina corundum ceramics, with hardness above HAR85;

Advantage

Wear resistance: alumina corundum ceramics with hardness above HAR85;

Impact resistance: the toughened ceramic formula ensures that the ceramic is not easy to break. The unique spherical design and high-quality buffer layer can resist the impact of large materials;

High temperature resistance: 250 ° C for a long time;

Acid and alkali resistant rubber adopts a new formula of acid and alkali resistant rubber, which can resist weak acid and weak alkali;

Anti falling off: ceramic rubber steel plate - body vulcanization, and the combination is very firm; Each ceramic has a penetrating bolt passing through the bottom steel plate and is firmly welded with double safety;

Convenient installation and replacement: it is provided with a whole lining plate to facilitate replacement and installation and reduce after-sales service;

Specifications

The use of wear-resistant ceramics can greatly save maintenance time and costs, and at least increase the service life of the equipment by more than 10 times.

| Size(mm) | Length/Width(mm) | Ceramic Thickness(mm) | Rubber Thickness(mm) | Rubber Thickness(mm) |

| 250×250×15 | 250/250 | 5 | 5 | 5 |

| 300×300×16 | 300/300 | 8 | 4 | 4 |

| 500×500×25 | 500/500 | 15 | 4 | 6 |

| 500×600×30 | 500/600 | 20 | 6 | 4 |

| 600×300×35 | 600/300 | 25 | 6 | 4 |

| 400×500×38 | 400/500 | 25 | 7 | 6 |

| 300×400×50 | 300/400 | 30 | 12 | 8 |

| 300×300×63 | 300/300 | 50 | 7 | 6 |

| 300×400×130 | 300/400 | 100 | 18 | 12 |

Further dimensions on demand.

Ceramic Tile Specifications | |

AL2O3(%) | 95±0.5 |

Bending Strength(Mpa) | >280 |

Fracture Toughness(MPam1/2) | >3.9 |

Rockwell Hardness(HRA) | >88 |

Wear Volume(cm3) | <0.3 |

Density(g/cm3) | >3.7 |

Items | Data |

Tensile Strength(Mpa) | ≥14 |

Break Extension(%) | ≥350 |

Shore Hardness(degree) | 55-65 |

Break Permanent Deformation(%) | ≤24 |

Rubber and Ceramic Adhesion Force(Mpa) | ≥3.0 |

Temperature Resistance(°C) | ≤100 |

The rubber and ceramic composite wear-resistant products is a customized product, it can be made in various shapes, selected composite material according liner wear of various thicknesses, forming a strong wear layer.

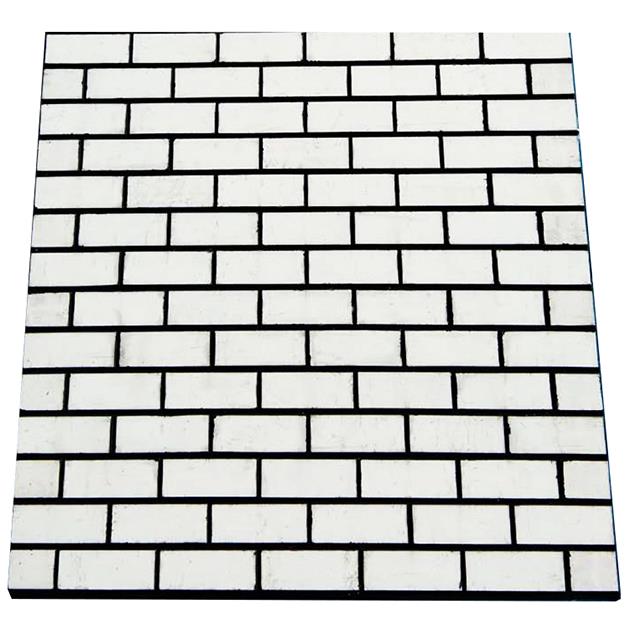

Square bricks: 10x10x2~10mm, 17.5x17.5x2~15mm,20x20x2~15mm,33x33x7~25mm, etc.

Ceramic plate: 100x100x6~50mm, 150x100X6~50mm, etc.

Hexagonal tiles: S12xT3~20mm, S19xT6~25mm

Ceramic tiles: 40x40x40mm, 32x32x22mm, 38x38x38mm, etc.

Ceramic cylinder/rod: 6x6mm, 15x15mm, 20x20mm, 31x31mm, 40x40mm, 50x50mm, etc.

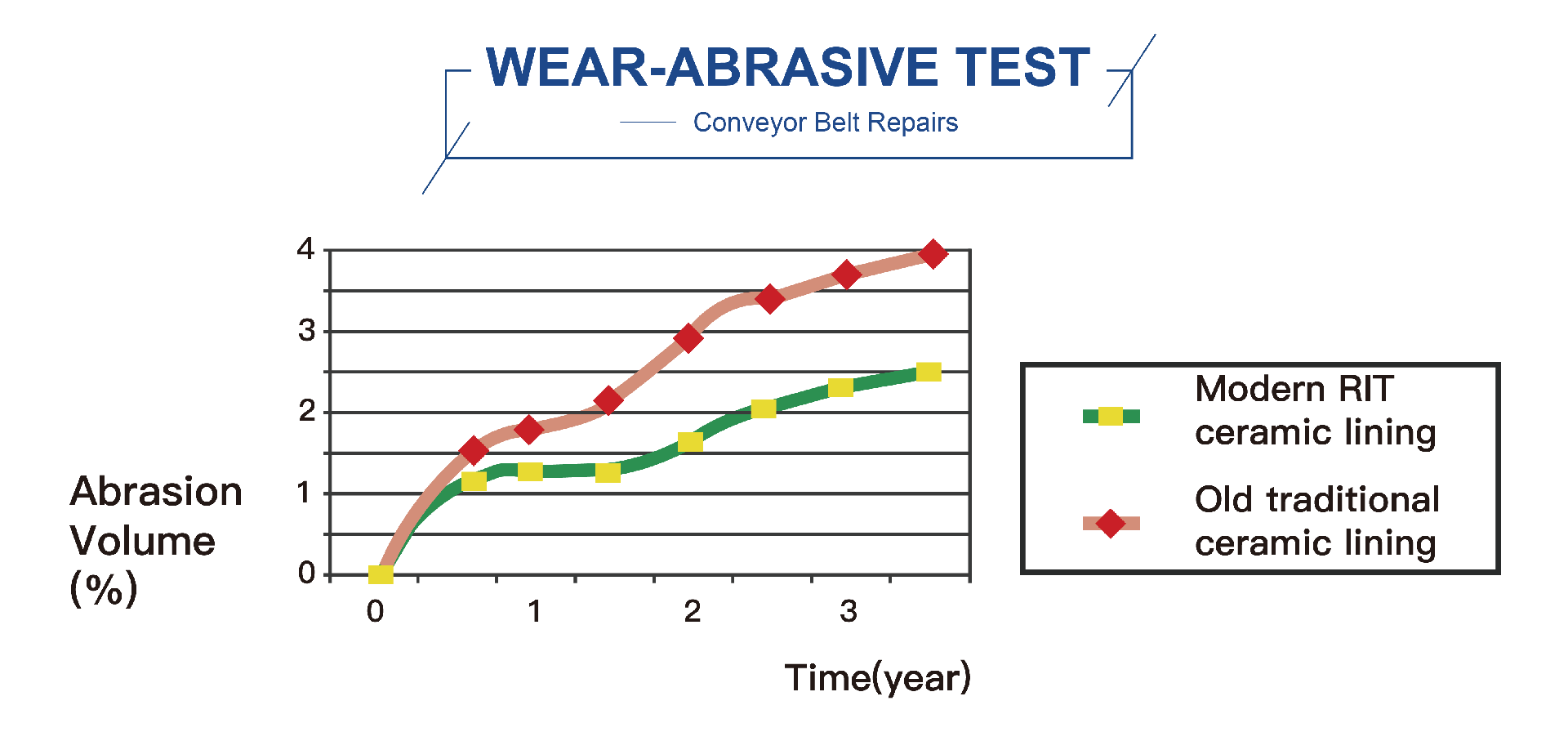

The unique toughening formula forms a strong crystal bond, which greatly enhances the impact resistance of alumina ceramics, which is 3 to 5 times that of general standard wear-resistant ceramics.

The raw materials of the rubber and ceramic composite wear-resistant are high-purity alpha alumina and crystal growth inhibitor. Powder prepared using the most advanced powder technology to ensure flowability of the granulated powders made uniform distribution possessed good.