Conveyor Roller Idler Group

Brand: BAI-OTT or OEM

Feature: Abrasion and impact resistance

Size: Available

Material: Carbon steel+Rubber

Sample: Provide

MOQ: 10 Sets

Sample: Provide

Product Inspection:Available

Application: Coal mines, Cement plants, Steel plants, Power plants and other factories

Lead time:Ready to ship in stock

View more Conveyor Idler Roller from BAI-OTT

Description

Idler Group

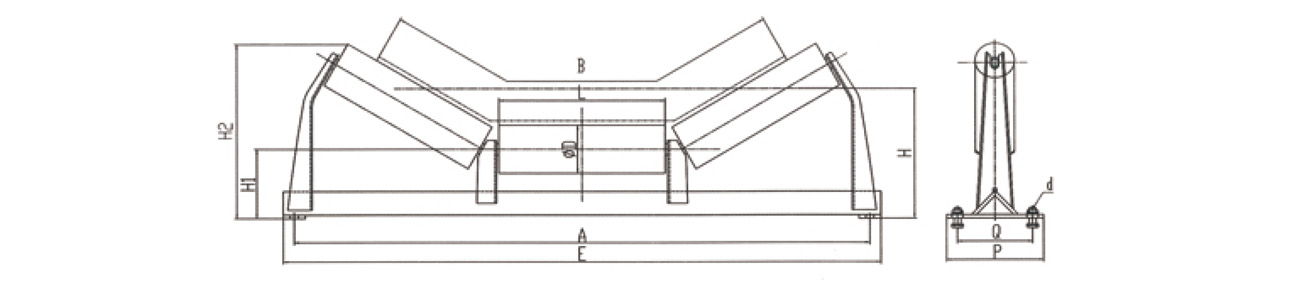

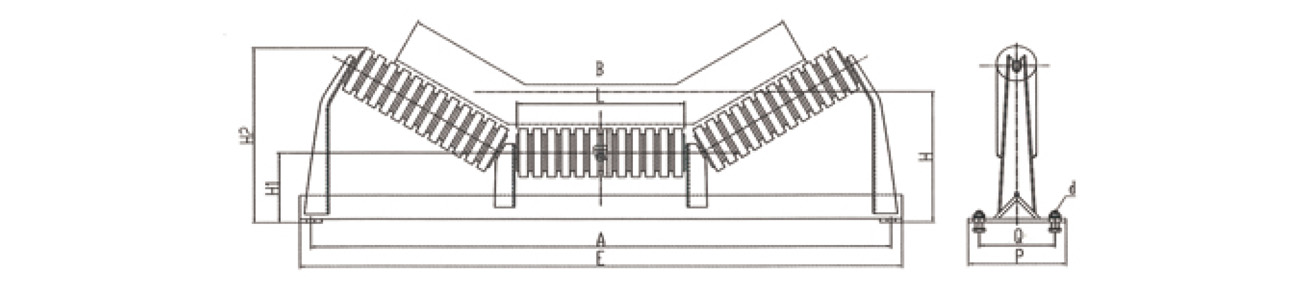

This series of idler sets is composed of triple group idler and movable detachable idler support frame, which is composed of bottom beam and movable triangular strut. The idler group takes the pressure spring as the buffer force source, and uses the performance that the elastic force will increase with the decrease of height when the pressure spring is compressed, so that the buffer elastic force of the idler group can increase with the increase of impulse force, which can effectively offset the impact force of material falling and protect the tape. The movable triangular support of the idler group can decompose the impact force acting on the idler strut, which can effectively increase the impact resistance of the idler group and prolong the service life. The roller group is durable, does not drop the roller, and the roller frame does not change. It has obvious protective effect on the tape.

Ⅱ Bottom beam

The bottom beam is a channel steel weldment with good strength, stiffness and stability. The utility model overcomes the defect of the deformation of the bottom beam of the buffer idler group of some large impact conveyor. The tray on the bottom beam is 35# steel casting, which plays the role of dragging the spring and controlling the bottom dead center of the middle idler.

Ⅲ Movable triangular support column

The movable triangular support column is composed of movable outrigger, pressure spring and guide strut assembly, which is movably connected with the bottom beam.

Advantage

Stable operation, stable quality and maintenance free.

Small diameter jump, smooth rotation and long service life.

Multi channel labyrinth seal and prevent the invasion of dust and water.

High precision special steel pipe ensures low vibration and low noise of idler.

Specifications

Our company specializes in the production of idler groups. The role of idler is to support the conveyor belt and material weight. The operation of idler group must be flexible and reliable. Reducing the friction between conveyor belt and idler plays a key role in the service life of conveyor belt, which accounts for more than 25% of the total cost of conveyor. Although the idler group is a small part in the belt conveyor and its structure is not complex, it is not easy to manufacture a high-quality idler group. Mining idler is widely used in mining, and coal mine idler is also widely used. We supply special mining idler, coal mine idler and coal mine idler. Our factory also produces more idler related products, which can fully meet your needs.

UNIT:MM

Belt width(B) | Drawing No. | Roller | Bearing No. | A | E | H | H1 | H2 | P | Q | d | Bracket Thickness | Bottom Bracket Thickness | Angle No. | Bracket Weight(KG) | |

D | L | |||||||||||||||

500 | TD1C1 | 89 | 190 | 204 | 720 | 760 | 210 | 125.5 | 266 | 170 | 130 | M12 | 3.0 | 6.0 | 63*63*6 | 6.73 |

650 | TD2C1 | 89 | 240 | 204 | 870 | 910 | 230 | 125.5 | 291 | 170 | 130 | M12 | 3.0 | 6.0 | 63*63*6 | 7.94 |

800 | TD3C1 | 89 | 305 | 204 | 1070 | 1110 | 240 | 125.5 | 323 | 170 | 130 | M12 | 3.0 | 6.0 | 63*63*6 | 9.13 |

1000 | TD4C1 | 108 | 375 | 305 | 1300 | 1350 | 300 | 156 | 400 | 220 | 170 | M16 | 4.0 | 8.0 | 75*75*8 | 17.84 |

1200 | TD5C1 | 108 | 455 | 305 | 1550 | 1610 | 330 | 176 | 460 | 260 | 200 | M16 | 4.0 | 10.0 | 100*100*8 | 27.3 |

1400 | TD6C1 | 108 | 525 | 305 | 1750 | 1810 | 350 | 176 | 495 | 260 | 200 | M16 | 4.0 | 10.0 | 100*100*8 | 30 |

UNIT:mm

Belt Width(B) | Drawing NO. | Roller | Bearing No. | A | E | H | H1 | H2 | P | Q | d | Bracket Thickness | Bottom Bracket Thickness | Angle No. | Bracket Weight(KG) | |

D | L | |||||||||||||||

500 | TD1C9 | 89 | 190 | 204 | 720 | 760 | 210 | 125.5 | 266 | 170 | 130 | M12 | 3.0 | 6.0 | 63*63*6 | 6.73 |

650 | TD2C9 | 89 | 240 | 204 | 870 | 910 | 230 | 125.5 | 291 | 170 | 130 | M12 | 3.0 | 6.0 | 63*63*6 | 7.94 |

800 | TD3C9 | 89 | 305 | 204 | 1070 | 1110 | 240 | 125.5 | 323 | 170 | 130 | M12 | 3.0 | 6.0 | 63*63*6 | 9.13 |

1000 | TD4C9 | 108 | 375 | 305 | 1300 | 1350 | 300 | 156 | 400 | 220 | 170 | M16 | 4.0 | 8.0 | 75*75*8 | 17.84 |

1200 | TC5C9 | 108 | 455 | 305 | 1550 | 1610 | 330 | 176 | 460 | 260 | 200 | M16 | 4.0 | 10.0 | 100*100*8 | 27.3 |

1400 | T06C9 | 108 | 525 | 305 | 1750 | 1810 | 350 | 176 | 495 | 260 | 200 | M16 | 4 0 | 10.0 | 100*100*8 | 30 |