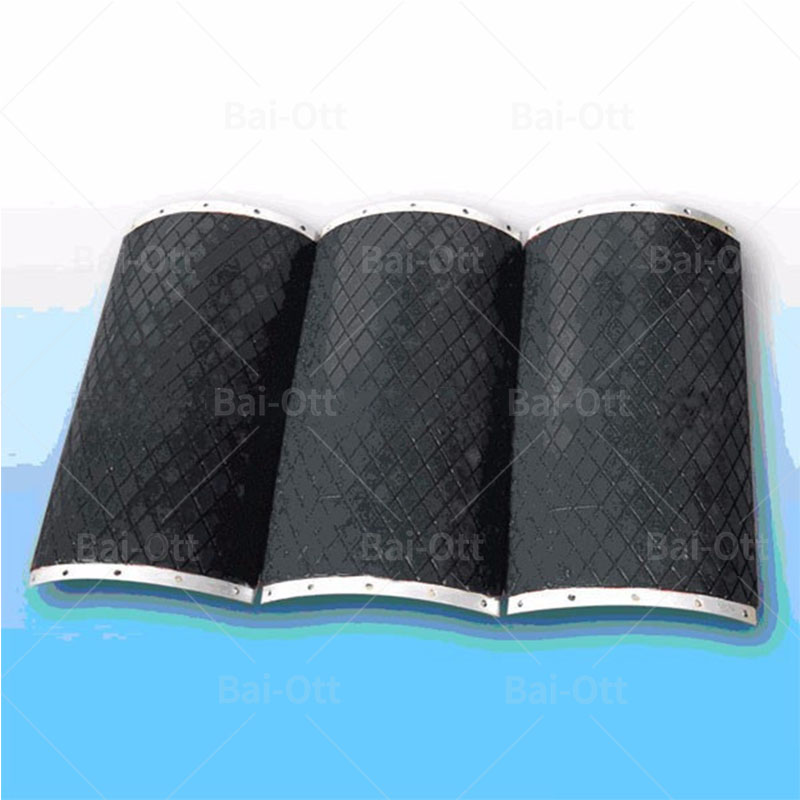

Bolt On Diamond Pulley Ceramic Lagging

Brand: BAI-OTT or OEM

Thickness: 12mm,15mm,20mm or Custom

Feature: Wear-Resistant and quick

Installation: Head Drum and Tail Drum

CN Bonding: Available

Material: Rubber

Sample: Provide

Product Inspection:Available

MOQ: 1 Square Meter

Lead time:Ready to ship in stock

View more Pulley Lagging Sheet from BAI-OTT

Description

Bolt On Diamond Pulley Ceramic Lagging

The shell pulley lagging is composed of tile shell rubber plate and retainer. The retainer is welded on the drum and pressed against the tile shell rubber plate during installation. Tile shell rubber plate is made of wear-resistant rubber layer and metal layer by thermal vulcanization. According to different thickness, the tile shell rubber plate can be divided into 12mm, 15mm and 20mm.

Used for drum lagging in wet and muddy conditions, which has the characteristics of high friction, anti-slip, high wear-resistant, heat resistant. And can provide distinguished grasping force between driving roller and conveyor belt, accommodate to all kinds of muddy, humid, and sticky working environment, also work well to solve severe wear and slipping problems of the drive wheel, tailwheel, tension pulley, and roller, ensuring the conveyor belt running well. And especially suitable for the muddy and damp difficult conveyor working environment because the ceramic is strong enough to protect the tiles and conveyor pulley.

Coal washing plant, Cement plant, Metal factory, Metallurgical plant, Crusher like ceramic pulley lagging because their conveyor tile location in the damp places, the ceramic outstanding in high wear-resistant can better belt the conveyor running.

| Order No. | Product Name | Dimension(mm) |

| 3931250 | Bolt On Pulley Ceramic Lagging | 12*500*10000 |

| 3931550 | Bolt On Pulley Ceramic Lagging | 15*500*10000 |

| 3932050 | Bolt On Pulley Ceramic Lagging | 20*500*10000 |

Further dimensions on demand

Advantage

The drum does not need to be disassembled;

Quick and convenient maintenance and replacement;

The adhesive layer is wear-resistant and has long service life;

The product is suitable for rollers of various specifications.

Specifications

Wear resistance: It is made of high elasticity and high wear-resistant rubber raw materials.

Friction: Diamond groove and z-groove assist the belt to operate, and the friction and traction force are doubled.

Heat dissipation: The groove and the gap between the insert plates can play a good effect on heat dissipation and reduce the degree of friction heat.

Adaptability: Meet the needs of cold resistance ,high temperature resistance, anti-static, anti flame retardant, non-toxic and other index requirements.

Customized: Customized according to the drum size of different specifications and models to meet the needs of each diameter and length of drum.