Motorized Secondary PU Belt Cleaner Machine

Brand: BAI-OTT or OEM

Belt Width: 800mm-2000mm

Feature: Wear-Resistant,Adjustment,Design

Material: PU

MOQ: 1 Set

Sample: Provide

Product Inspection:Available

Application: Coal mines, Cement plants, Steel plants, Power plants and other factories

Lead time: Ready to ship in stock

View more Conveyor Belt Cleaner from BAI-OTT

Description

Secondary PU belt cleaner also named water Sweeper Cleaner, is usually be put behind the secondary Tungsten cleaner to further remove the tiniest and muddy material such as water and powder.

Flat top and 85 Shore A PU material can softly touch the belt bottom so that can clean the rest tiny material well. The adjustable tensioner part can make it very easy to be modified as the conveyor frame.

BAI-OTT is a professional manufacturer of conveyor belt cleaner and scraper in China. The cleaners we design and manufacture are Light duty PU primary belt Cleaner, Heavy duty primary PU belt scraper, Constant pressure primary belt sweeper, Alloy primary belt cleaner (H type), Ceramic belt cleaner, Medium-sized primary conveyor sweeper, secondary scraper sweeper, second alloy sweeper,second constant pressure sweeper, universal alloy sweeper, Tail V-plow conveyor sweeper, central I-type conveyor cleaner, electric roller brush cleaner and sweeper blade.

| Order No. | Product Name | Belt Width(mm) | Blade Width(mm) | Extension Bar(mm) |

| 7855165 | Secondary PU Belt Cleaner Machine | 650 | 650 | 650 |

| 7855180 | Secondary PU Belt Cleaner Machine | 800 | 800 | 650 |

| 7855110 | Secondary PU Belt Cleaner Machine | 1000 | 1000 | 650 |

| 7855112 | Secondary PU Belt Cleaner Machine | 1200 | 1200 | 850 |

| 7855114 | Secondary PU Belt Cleaner Machine | 1400 | 1400 | 850 |

| 7855116 | Secondary PU Belt Cleaner Machine | 1600 | 1600 | 850 |

| 7855118 | Secondary PU Belt Cleaner Machine | 1800 | 1800 | 850 |

| 7855120 | Secondary PU Belt Cleaner Machine | 2000 | 2000 | 850 |

Advantage

The unique tensioning device and high-performance spring can make the blade stick closely to the leather when the belt is constantly shaking.

It can maintain a stable tension, reduce the fatigue damage to the blade base caused by jitter, and improve the service life of the blade.

There is no need to disassemble the cleaner, just adjust the screw on the tensioner to adjust the tension of the knife edge. The cleaning effect is obvious, durable, and well-received by users.

Specifications

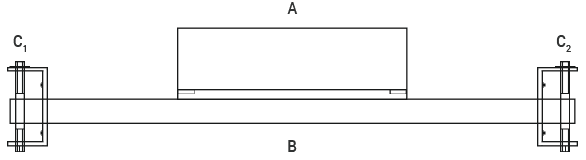

Orange Type:

| Belt Width(mm) | A(mm) | B(mm) | C(pcs) | Scraper Weight(KG) | Total Weight(KG) |

| 800 | 800 | 1650 | 2 | 5 | 24.4 |

| 1000 | 1000 | 1850 | 2 | 6.3 | 27.1 |

| 1200 | 1200 | 2050 | 2 | 7.6 | 30.4 |

| 1400 | 1400 | 2250 | 2 | 8.9 | 33.7 |

| 1600 | 1600 | 2450 | 2 | 10.2 | 37 |

| 1800 | 1800 | 2650 | 2 | 11.5 | 40.3 |

| 2000 | 2000 | 2850 | 2 | 12.8 | 43.6 |

Blue Type:

| Belt Width(mm) | A(mm) | B(mm) | C(pcs) | Scraper Weight(KG) | Total Weight(KG) |

| 800 | 800 | 1650 | 2 | 7.3 | 31.3 |

| 1000 | 1000 | 1850 | 2 | 8.6 | 34 |

| 1200 | 1200 | 2050 | 2 | 10.3 | 37 |

| 1400 | 1400 | 2250 | 2 | 12 | 40 |

| 1600 | 1600 | 2450 | 2 | 13.8 | 43 |

| 1800 | 1800 | 2650 | 2 | 15.5 | 46.2 |

| 2000 | 2000 | 2850 | 2 | 17.2 | 49.5 |

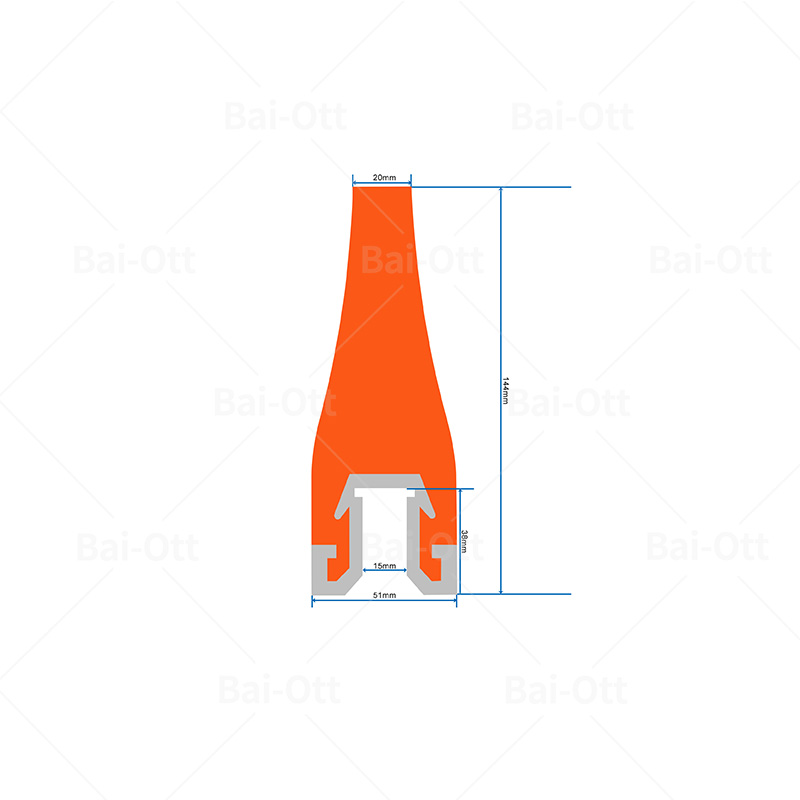

Blade Part:

This part touch conveyor belt bottom surface to clean the material on it.

Wear abrasive Polyurethane materail

Color can be customized

Temperature from -20 to 120°C available

Blade is detachable

Used in power plant, mining, port, cement plant

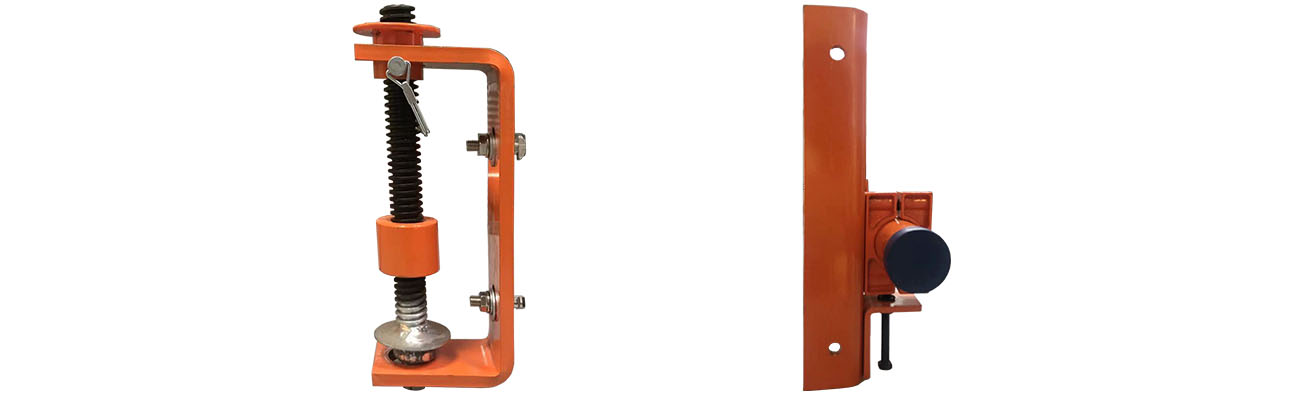

Tensioner Part:

Different tensioner types to meet various conveyor type and cleaning requirements.

The first tensioner is (L)*23(W)*25(H)cm which is small and porable to stall in many narrow and short distance between belt and conveyor frame.

2 bolts to install it on conveyor and 3 bolts fix it on cleaner tube.Esay operation 4kg for each.

The second tensioner is 18(L)*7(W)*45(H)cm which is taller to matched the higher distance between conveyor frame and bottom belt.

Larger adjustable range is convenient to operate.2 bolts to install it on conveyor and 3 bolts fix it on cleaner tube.

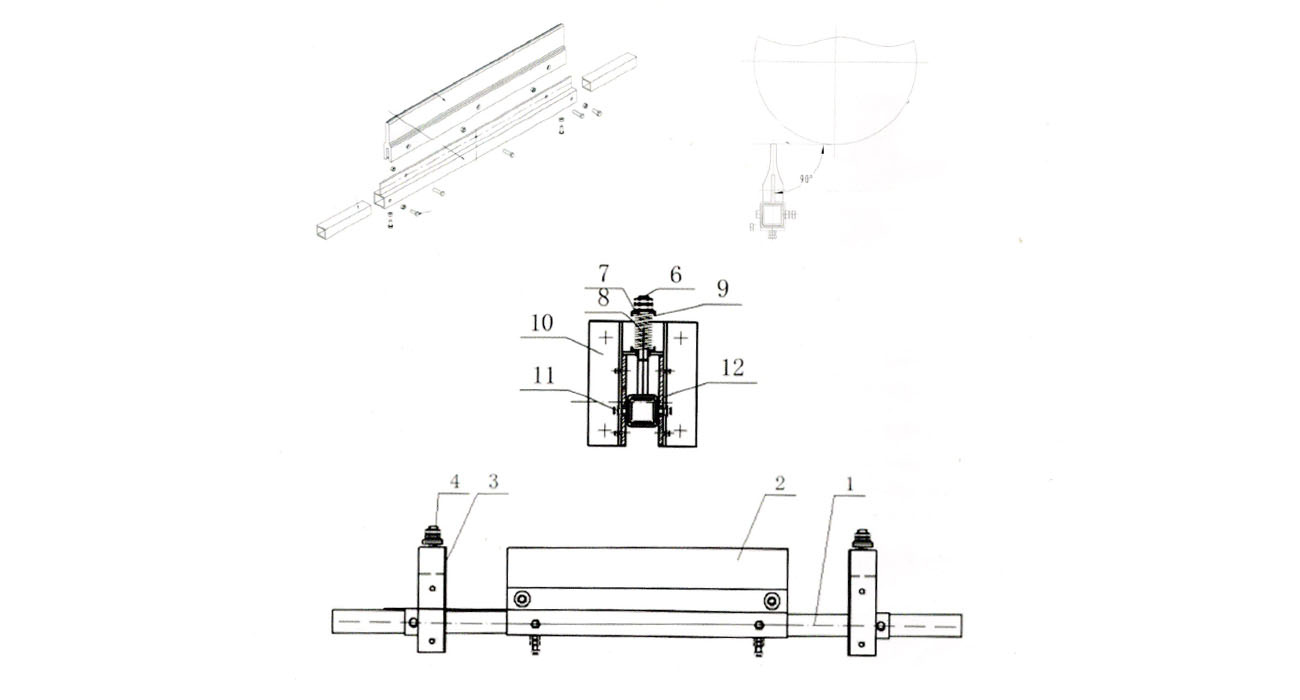

Installation Drawing

![[pics:title]](/static/upload/image/20220302/1646191058905950.jpg)