Secondary Torque Taurus Belt Cleaner

Brand: BAI-OTT or OEM

Belt Width: 650mm-2200mm

Feature: Wear-Resistant,Adjustment,Design

Tensile Strength: 53

Installation Site: Return Belt Tail Drum

Material: Alloy, Ceramic

MOQ: 1 Set

Sample: Provide

Product Inspection:Available

Lead time: Ready to ship in stock

View more Conveyor Belt Cleaner from BAI-OTT

Description

Secondary Torque Taurus Belt Cleaner

Secondary torque cleaners give you consistently superior cleaning results, even in the most demanding environments. A patented revolutionary bumper design pushes the cleaning blades to the belt surface and maintains contact between them.

BAI-OTT is a professional manufacturer of conveyor belt cleaner and scraper in China. The cleaners we design and manufacture are Light duty PU primary belt Cleaner, Heavy duty primary PU belt scraper, Constant pressure primary belt sweeper, Alloy primary belt cleaner (H type), Ceramic belt cleaner, Medium-sized primary conveyor sweeper, secondary scraper sweeper, second alloy sweeper,second constant pressure sweeper, universal alloy sweeper, Tail V-plow conveyor sweeper, central I-type conveyor cleaner, electric roller brush cleaner and sweeper blade.

| Order No. | Product Name | Belt Width(mm) | Blade Width(mm) | Installation Site |

| 7855165 | Secondary Torque Belt Cleaner | 650 | 650 | Return Belt Tail Drum |

| 7855180 | Secondary Torque Belt Cleaner | 800 | 800 | Return Belt Tail Drum |

| 7855110 | Secondary Torque Belt Cleaner | 1000 | 1000 | Return Belt Tail Drum |

| 7855112 | Secondary Torque Belt Cleaner | 1200 | 1200 | Return Belt Tail Drum |

| 7855114 | Secondary Torque Belt Cleaner | 1400 | 1400 | Return Belt Tail Drum |

| 7855116 | Secondary Torque Belt Cleaner | 1600 | 1600 | Return Belt Tail Drum |

| 7855118 | Secondary Torque Belt Cleaner | 1800 | 1800 | Return Belt Tail Drum |

| 7855120 | Secondary Torque Belt Cleaner | 2000 | 2000 | Return Belt Tail Drum |

| 7855122 | Secondary Torque Belt Cleaner | 2200 | 2200 | Return Belt Tail Drum |

Further Dimensions on Demand.

Advantage

The tungsten carbide scraper can quickly and thoroughly remove sticky and wet return materials.

The double spring tensioning system can absorb the shock when it collides with the mechanical fasteners.

It is a new solution for conveyor belt cleaning problems in harsh application environments, which not only brings long-lasting and efficient cleaning force, but also has low maintenance requirements.

Specifications

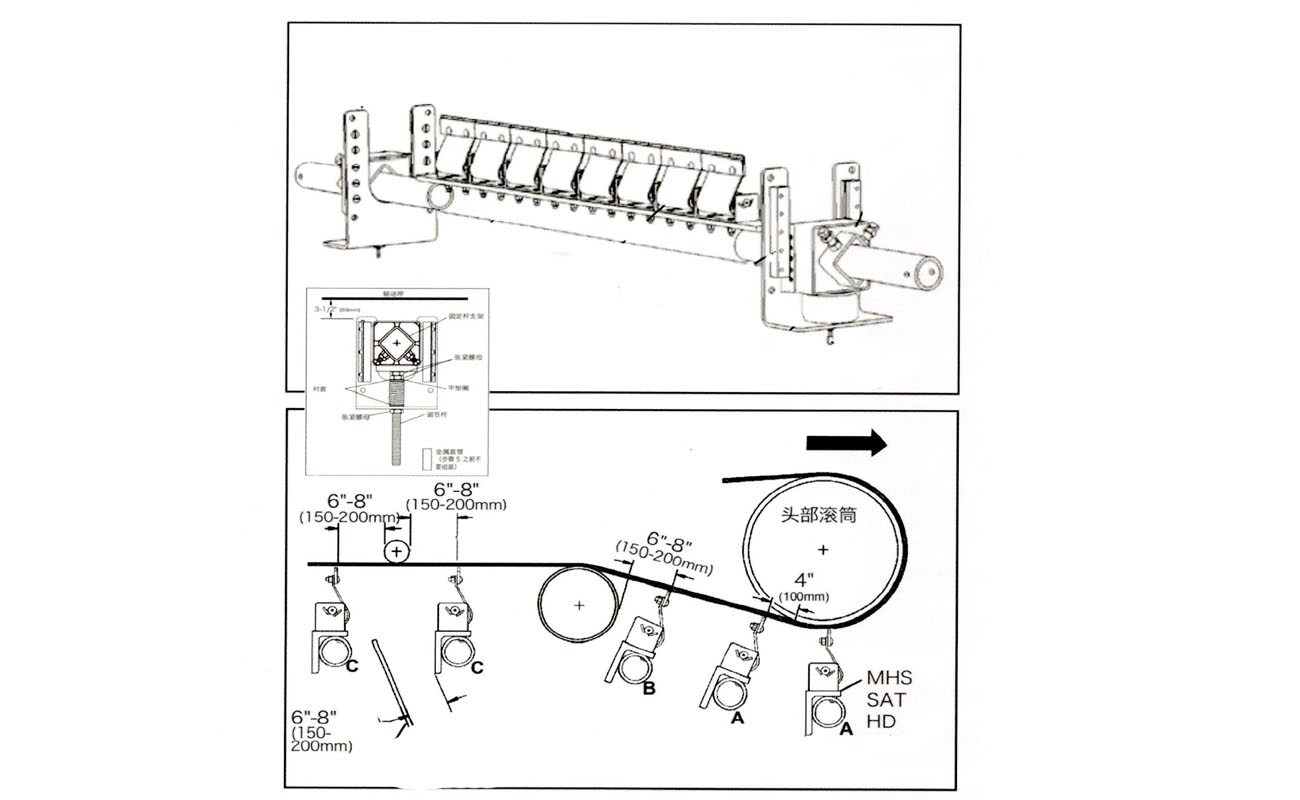

Outline design and installation drawings