High Elastic UHMWPE Conveyor Impact Bar

Brand: BAI-OTT or OEM

Feature: High elastic+Adjustable+High Wear-Resistant

Shape: Custom

Material: PE+Rubber+Steel Bolt

Sample:Available

Product Inspection:Available

Lead time:Ready to ship in stock

View more impact buffer beds from BAI-OTT

Description

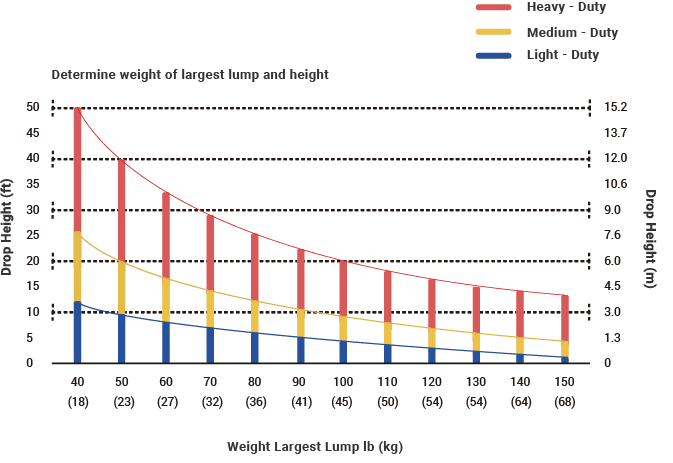

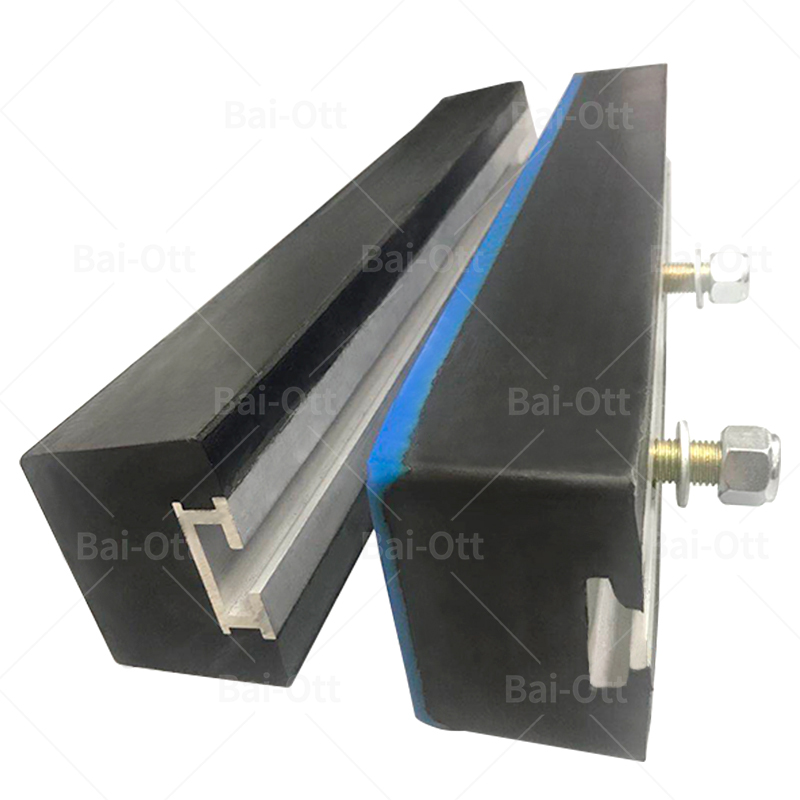

BAI-OTT Is one of the biggest Conveyor Impact Buffer Bar manufacturer that can customize the most suitable anti-slip coating as your requirements. Conveyor Impact Buffer Bar is used in the loading area of the belt conveyor to replace the traditional cushion rollers. It is designed to absorb impact loading which will dramatically reduce shock and stress loading to the structure and that has the best high wear resistance effect in the field of plastic materials. Even 9 times higher than metal stainless steel, the wear resistance rate is about 20 times that of A3 steel in an erosion environment.

| Item | Parameter | Standard Type | High Elastic Type | Downhole Type | |

UHMWPE Part | Color | Blue | Blue | Black | |

| Tensile breaking strength | Mpa | 23 | 23 | 20 | |

| Elongation at break | % | 300 | 300 | 250 | |

| Hardness | Shore A | 60-70 | 60-70 | 65-75 | |

| Abrasion | cm3 | 0.053 | 0.053 | 0.08 | |

| Density | g/cm3 | 0.93-0.94 | 0.93-0.94 | 1.13 | |

High Elastic Rubber Part | Hardness | Shore A | 60-65 | 45-50 | 60-65 |

| Strength of Extension | Mpa | 19 | 19 | 19 | |

| Elongation at break | % | 400 | 400 | 400 | |

| Metal Part | Type | Aluminium Alloy | |||

Bond Strength | Bonding of PE&rubber | N/mm | ≥10 | ≥10 | ≥10 |

| Bonding of metal&rubber | N/mm | ≥10 | ≥10 | ≥10 | |

Advantage

Conveyor impact buffer bar can effectively prevent the occurrence of uneven force on the conveyor belt and reduce the impact damage of the material;

The surface material is smooth and wear-resistant UHMW-PE, which can reduce frictional resistance and prolong life;

The middle layer of high elastic rubber of the impact bar can effectively absorb the impact of the material on the conveyor belt;

The bottom layer uses special high-strength steel parts, which is light and does not rust, easy to install, and the impact bar can be replaced by a single piece;

Conveyor impact buffer bar can be disassembled and assembled according to different carrying capacity, bandwidth and slot angle to improve production efficiency.

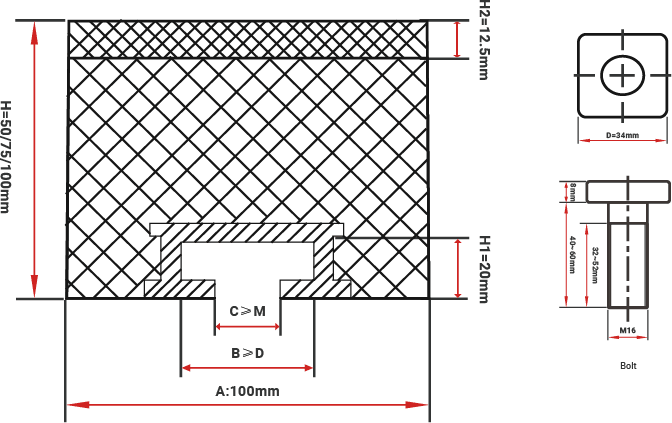

Specifications

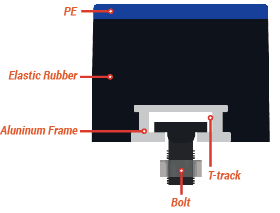

PE mainly height in 12.5mm,high wear resistance,low friction coefficient and high impact toughness;

The highly elastic rubber buffer layer absorbs the impact energy of falling materials on the conveyor belt;

The high-strength metal frame can withstand large load impact without deformation;

Steel bolts increase overall fastening;

The"T-track" device makes the buffer strip have different fastening points in the whole length to ensure the connection is firm and reliable and easy to disassemble;

The various parts are connected by hot vulcanizing technique.

![[pics:title]](/static/upload/image/20211227/1640596603514595.jpg)