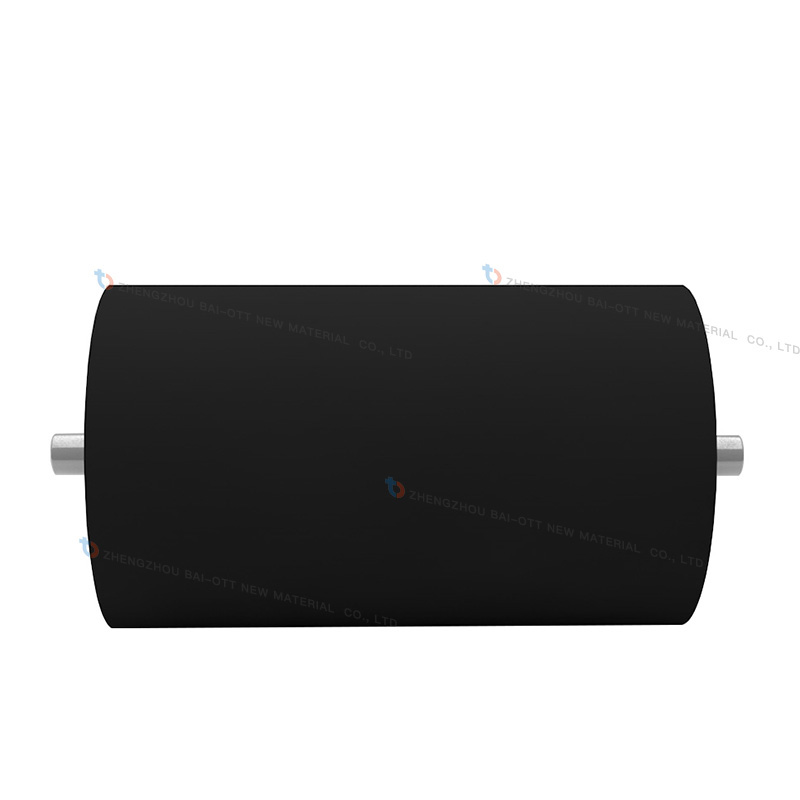

Conveyor Carrier Roller

Brand: BAI-OTT or OEM

Feature: Abrasion and impact resistance

Size: Available

Material: Carbon steel+Rubber

Sample: Provide

MOQ: 10 Sets

Sample: Provide

Product Inspection:Available

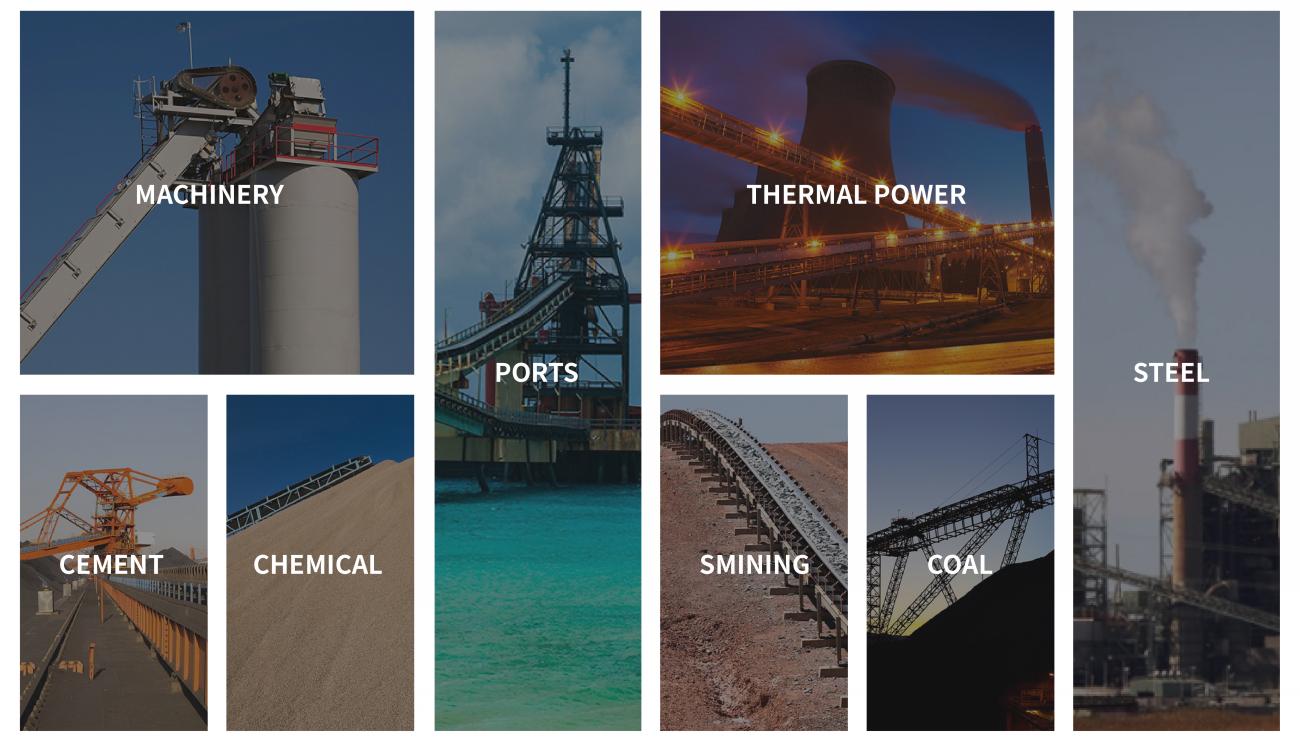

Application: Coal mines, Cement plants, Steel plants, Power plants and other factories

Lead time:Ready to ship in stock

View more Conveyor Idler Roller from BAI-OTT

Description

Roller is one of the most important parts of belt conveyor. According to the purpose of use, it can be divided into cerrier roller and return roller. According to the different use environment, it can be divided into roller for ordinary environment and roller for special environment.

Idler is an important part of belt conveyor, its function is to support the conveyor belt and material weight.The idlers can be divided into parallel idlers, buffer idlers, spiral idlers, altting idlers and groove idlers according to different structures.

Advantage

Excellent sealing performance

High load capacity (axial load)

Smooth operation, small revolving resistance, without block phenomenon

Easy for disassembly, Excellent maintainability and high reliability

Strong durability, at least 50000 hours work life

Specifications

The parallel roller Used for carrying conveyor belts and materials on belt conveyors without groove angle requirements. It has common type, comb type, forward dip type, steel glue type, spiral type, etc.

Buffer roller Installed at the receiving point of the conveyor to buffer the impact of the material on the conveyor belt when the material falls. It has spring plate type, buffer ring type, strong buffer type, adjustable elastic type, hanging type;

The aligning roller used to when the conveyor belt deviates from the center, correct the deviation of the conveyor belt to prevent the conveyor belt from being damaged. It has universal type, friction reversible type, strong type, cone type, spiral type, combined type, etc.

Groove idlers used to remove the sticky material on the conveyor belt, to keep an area clean.

It has common type, forward type, quick change bearing type, hanging type, variable groove Angle type, transition type, V type and so on.

According to different materials, it can be divided into ordinary steel roller ,Stainless steel roller, Hot dip galvanized roller, Wear-resistant cast iron roller, Ultra high molecular polyethylene roller, Wear-resistant ceramic roller, Nylon roller, Rubber coated roller.

The ultra high molecular polyethylene roller is used to instead of ordinary metal rollers, used in places with large dust and strong corrosiveness.

| Diameter(mm) | Length(mm) | Bearing Type |

| 89 | 180,190,200, 235,240,250, 275, 280,305,215, 350,375,380,455,465,600,750, 950,1150 | 204 |

| 108 | 190,200,240, 250,305,315, 360, 375,380,455, 465,525,530,600,700,750,790, 800,950,1150,1400,1600 | 204,205,305,306 |

| 133 | 305,375,380, 455,465,525, 530, 600,670,700, 750,790,800,900,950,1000,1100,1150,1400,1600, 1800, 2000, 2200 | 205,305,306 |

| 159 | 375,380,455,465,525,530,600,700,750, 790 ,800,900,1000,1050,1100,1120,1150,1250,1400,1500,1600,1700,1800,2000, 2200 ,2500,2800, 3000, 3150 | 305,306,308 |

| 193.7 | 2200, 2500, 2800, 3000, 3150, 3350 | 308,310 |

| 217 | 600,640,1050,1120,1600,1700,3150,3350 | 308,310 |

![[pics:title]](/static/upload/image/20220111/1641870102468911.jpg)