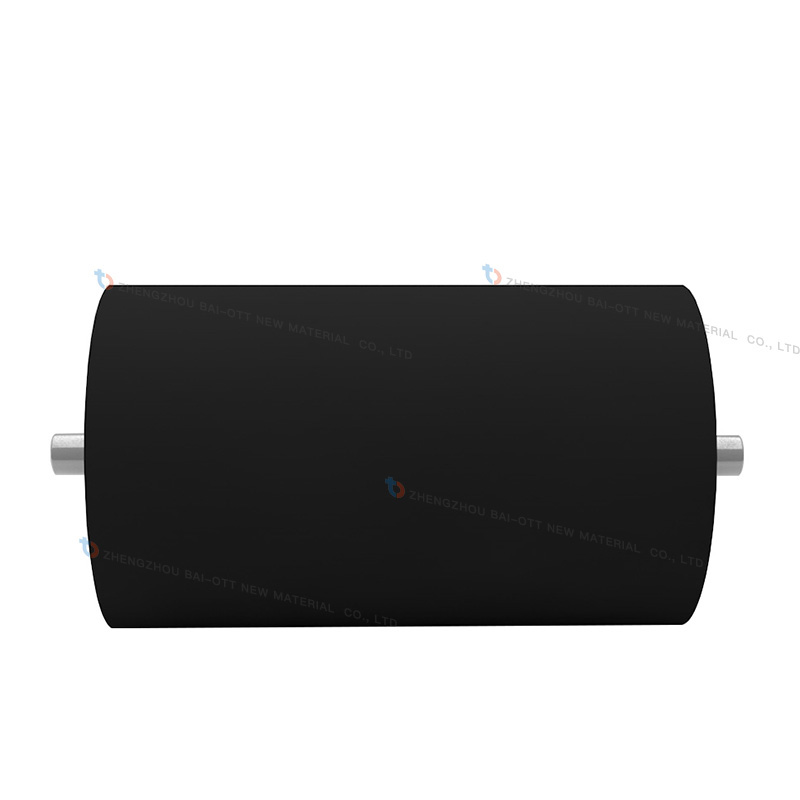

Good Quality Hot Vulcanized Plain Pulley Lagging Sheet

Brand: BAI-OTT or OEM

Thickness: 10mm,12mm,15mm,20mm or Custom

Feature: Wear-Resistant

CN Bonding: Available

Material: Rubber

Sample: Provide

Product Inspection:Available

MOQ: 1 Square Meter

Lead time: Ready to ship in stock

View more Pulley Lagging Sheet from BAI-OTT

Description

Good Quality Hot Vulcanized Plain Rubber Pulley Belt Slide Lagging Sheet

Plain pulley lagging sheet is the most popular lagging materials to increase the friction coefficient between the conveyor belt and the drum to improve the transportation efficiency of the conveyor system. It is an effective material to prevent accidental damage to the conveyor belt caused by the deviation of the conveyor belt. Which is easy to maintain the staff roller and reduce the operating costs of the conveyor line. You can cut on any pattern as your conveyor belt situation to make it easier.

| Order No. | Product Name | Dimension(mm) |

| 3512110 | Plain Pulley Lagging sheet | 10*2000*10000 |

| 3512112 | Plain Pulley Lagging sheet | 12*2000*10000 |

| 3512115 | Plain Pulley Lagging sheet | 15*2000*10000 |

| 3512120 | Plain Pulley Lagging sheet | 20*2000*10000 |

Further dimensions on demand

Advantage

Easy to install, you can cut any pattern as you want

Minimum wastage and economically priced

Customized solutions for customers based on the on-site environment

Customize rubber sheet diamond size is available

Hardness same as conveyor belt so better friction and protection to the belt.

Abundantly elastic basement rubber can protect conveyor belt well.

OEM for logo,and thickness is available.

CN bonding layer on back of the lagging so can directly brush glue without grind step.

Specifications

| Raw Material | BR/IR/SBR |

| Density | 1.2g/cm3 |

| Hardness | 60±5 shore A |

| Wear Abrasive | 63mm3 at 10N |

| Tensile Strength | 18-20MPA |

| Breaking Strength | 20MN/M2[MIN] |

| Elongation | 450%MIN |

| Color | Black |

| Water Absorption | 0% |

| Thickness | 10/12/15/20mm |

| Uncured boding layer | Directly stick needn't buffing it |