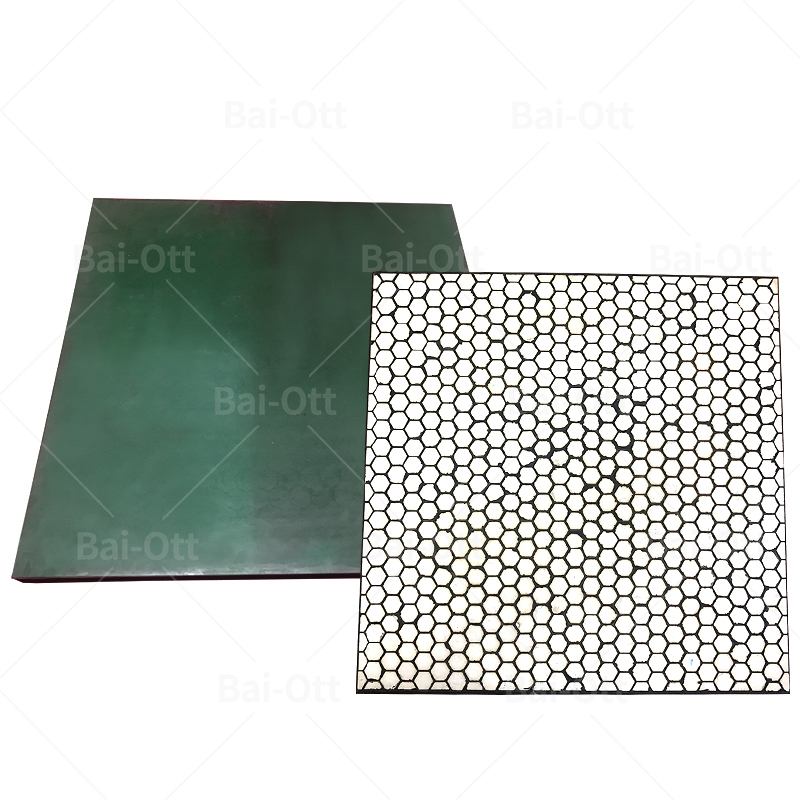

Alumina Ceramic Lining Sheet

Brand: BAI-OTT or OEM

Bending Strength(Mpa): >280

Feature: Abrasion and impact resistance

Size: Available

Material: Ceramic+Rubber+Polyurethane

Sample: Provide

MOQ: 1 Square Meter

Lead time:Ready to ship in stock

View more Ceramic Lining from BAI-OTT

Description

Alumina Ceramic Lining Sheet

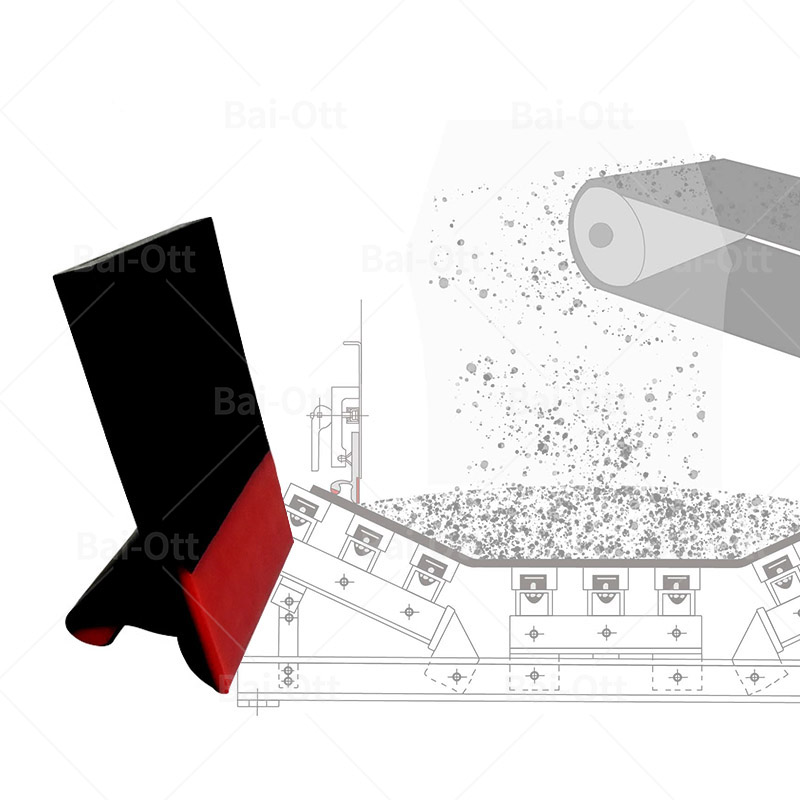

The rubber and ceramic composite wear-resistant products is to use the hot vulcanization process to vulcanize the toughened ceramic sheet in a steel plate groove equipped with special rubber, and the steel plate groove is equipped with countersunk bolts.Ceramic lining is divided into two-in-one liner and three-in-one liner.Two-in-one lining refers to the composite of ceramic and rubber.Three-in-one lining refers to the composite of ceramic, rubber and steel plate. And it comes with bolts for easy installation.

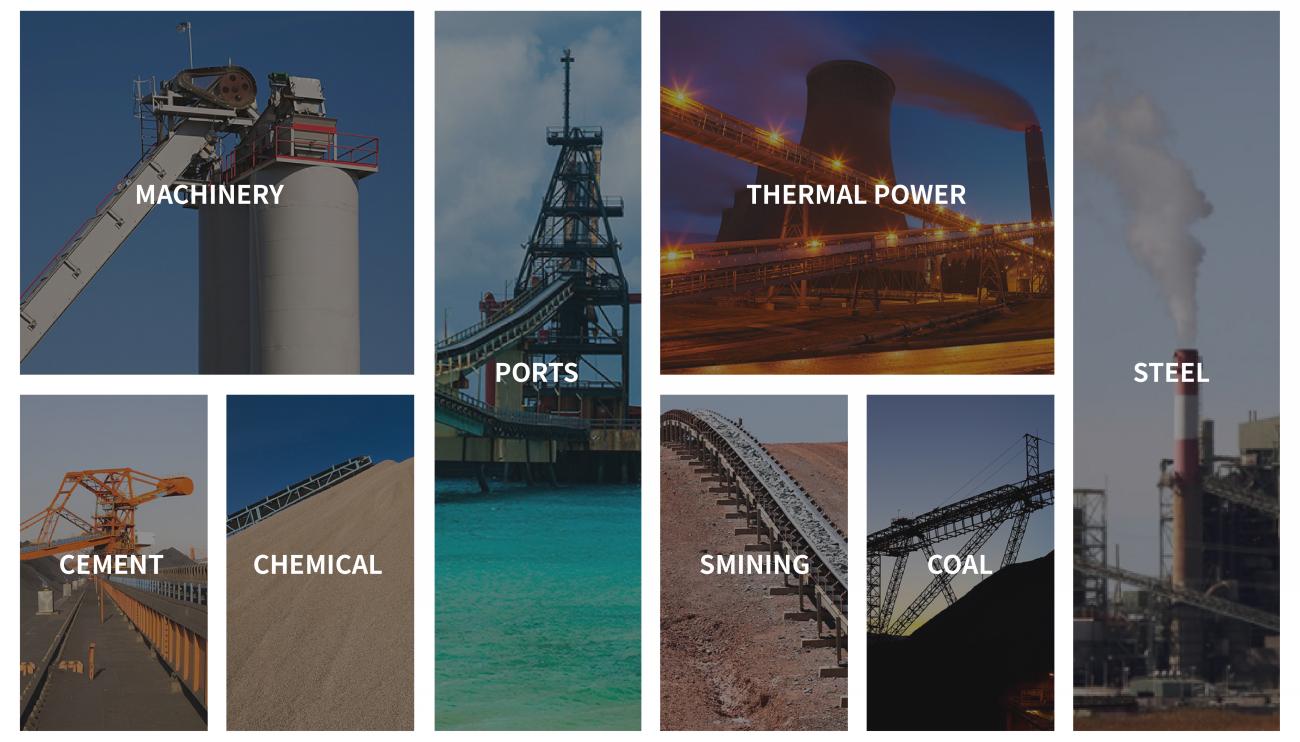

It is widely used in coal handling, material conveying system, pulverizing system, ash discharge, dust removal system and all mechanical equipment with great wear in thermal power, steel, smelting, machinery, coal, mining, chemical, cement, port and wharf enterprises, etc. Different types of products can be selected according to different needs.

Advantage

Good buffering performance

Convenient construction

No sticking and no blocking

Specifications

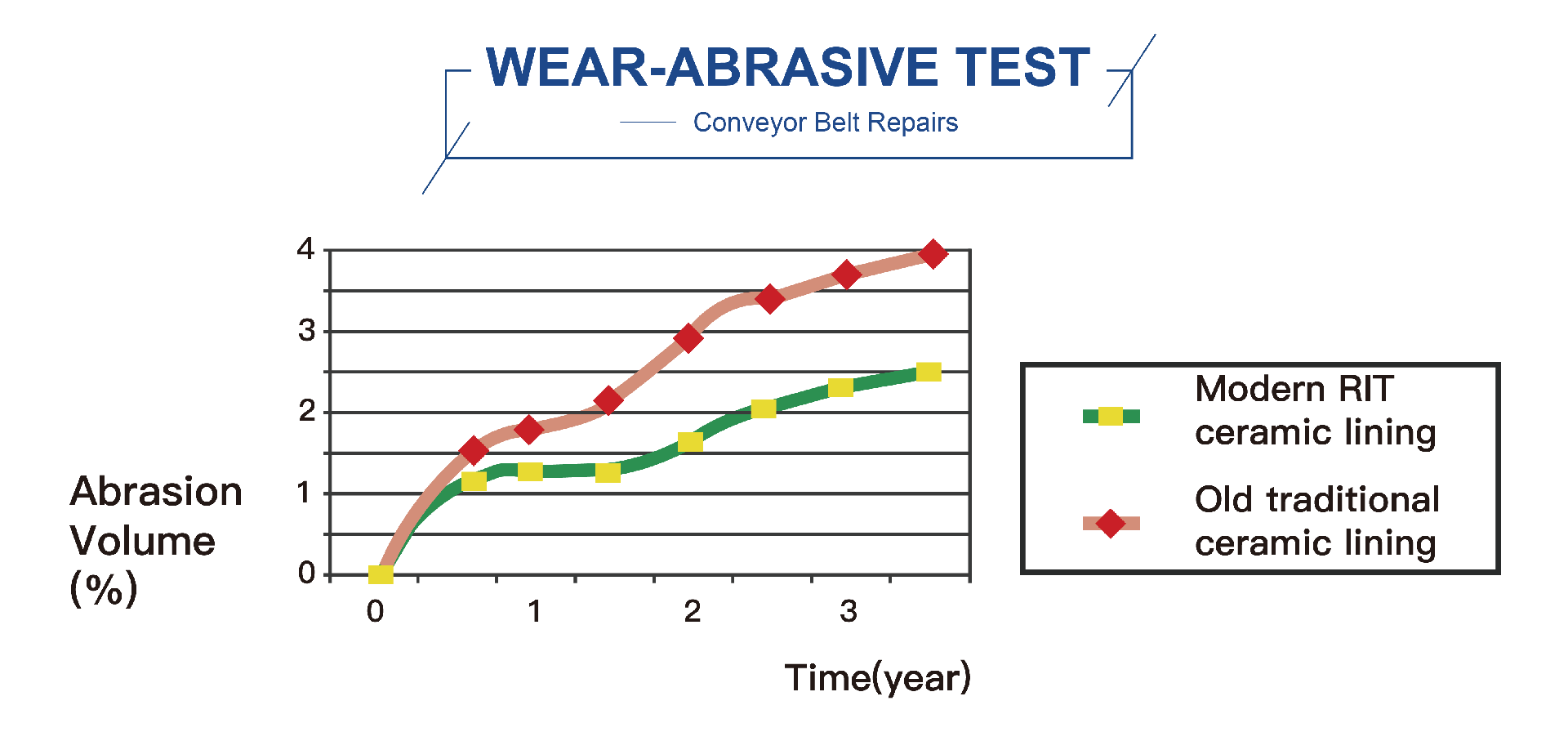

The use of wear-resistant ceramics can greatly save maintenance time and costs, and at least increase the service life of the equipment by more than 10 times.

| Size(mm) | Length/Width(mm) | Ceramic Thickness(mm) | Rubber Thickness(mm) | Rubber Thickness(mm) |

| 250×250×15 | 250/250 | 5 | 5 | 5 |

| 300×300×16 | 300/300 | 8 | 4 | 4 |

| 500×500×25 | 500/500 | 15 | 4 | 6 |

| 500×600×30 | 500/600 | 20 | 6 | 4 |

| 600×300×35 | 600/300 | 25 | 6 | 4 |

| 400×500×38 | 400/500 | 25 | 7 | 6 |

| 300×400×50 | 300/400 | 30 | 12 | 8 |

| 300×300×63 | 300/300 | 50 | 7 | 6 |

| 300×400×130 | 300/400 | 100 | 18 | 12 |

Further dimensions on demand.

Ceramic Tile Specifications | |

AL2O3(%) | 95±0.5 |

Bending Strength(Mpa) | >280 |

Fracture Toughness(MPam1/2) | >3.9 |

Rockwell Hardness(HRA) | >88 |

Wear Volume(cm3) | <0.3 |

Density(g/cm3) | >3.7 |

Items | Data |

Tensile Strength(Mpa) | ≥14 |

Break Extension(%) | ≥350 |

Shore Hardness(degree) | 55-65 |

Break Permanent Deformation(%) | ≤24 |

Rubber and Ceramic Adhesion Force(Mpa) | ≥3.0 |

Temperature Resistance(°C) | ≤100 |

The rubber and ceramic composite wear-resistant products is a customized product, it can be made in various shapes, selected composite material according liner wear of various thicknesses, forming a strong wear layer.

Square bricks: 10x10x2~10mm, 17.5x17.5x2~15mm,20x20x2~15mm,33x33x7~25mm, etc.

Ceramic plate: 100x100x6~50mm, 150x100X6~50mm, etc.

Hexagonal tiles: S12xT3~20mm, S19xT6~25mm

Ceramic tiles: 40x40x40mm, 32x32x22mm, 38x38x38mm, etc.

Ceramic cylinder/rod: 6x6mm, 15x15mm, 20x20mm, 31x31mm, 40x40mm, 50x50mm, etc.

The unique toughening formula forms a strong crystal bond, which greatly enhances the impact resistance of alumina ceramics, which is 3 to 5 times that of general standard wear-resistant ceramics.

The raw materials of the rubber and ceramic composite wear-resistant are high-purity alpha alumina and crystal growth inhibitor. Powder prepared using the most advanced powder technology to ensure flowability of the granulated powders made uniform distribution possessed good.